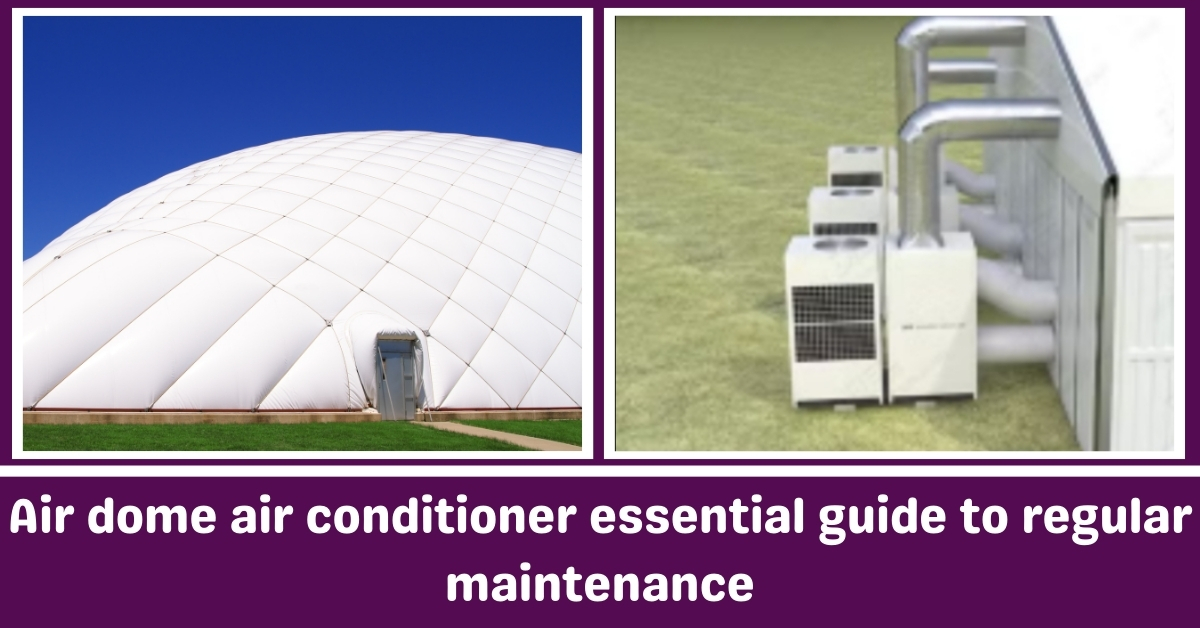

Air dome structures are becoming increasingly popular across industries from sports facilities and event arenas to storage warehouses and temporary industrial spaces.

One of the most critical components that keeps these inflatable environments functional and comfortable is the air dome air conditioner. Unlike standard HVAC systems, these units do more than just cool the air.

They play a crucial role in maintaining internal pressure, managing humidity, and supporting structural integrity.

Due to the unique nature of air-supported domes, even a minor disruption in temperature or pressure can lead to operational issues or full system failure.

That’s why regular and consistent maintenance isn’t just a good idea it’s essential. When these systems run non-stop during peak usage seasons, wear and tear becomes inevitable.

Without proper care, you’re looking at rising energy bills, unexpected breakdowns, and potentially costly repairs.

According to HVAC industry data, dirty coils alone can reduce system efficiency by up to 30%, while something as simple as a clogged filter can trigger compressor failure.

Add to that the risk of humidity-related damage or a drop in dome pressure, and the stakes are high. The truth is, the longer you delay maintenance, the more you risk your dome’s functionality and safety.

Whether you manage a single air dome or a network of climate-controlled structures, understanding the basics of maintenance can save you time, money, and stress.

Air dome air conditioner essential guide to regular maintenance

In this guide, we will explain the complete process of maintaining an air dome air conditioner, from daily checks to annual inspections so you can keep your system running at peak performance all year round.

1. Real Cost of Poor Maintenance

Neglecting regular maintenance of your air dome air conditioner can lead to significant financial losses, both in the short term and over the long run.

The repercussions of poorly maintained systems extend beyond just repairs; they affect your operational efficiency, energy usage, and overall equipment lifespan.

Let’s break down the real cost of poor maintenance.

Increased Energy Consumption

When your air dome air conditioner isn’t properly maintained, its efficiency drops dramatically. Dirty filters, clogged coils, or improperly calibrated systems force the unit to work harder to achieve the same cooling or pressure levels.

A typical air dome air conditioner can use up to 50% more energy if the system is not cleaned regularly.

This increase in energy consumption can translate to higher electricity bills, often reaching thousands of dollars annually.

If you’re running a large facility with multiple units, these added costs become even more pronounced.

Expensive Repairs

Air conditioners, like any mechanical system, have parts that wear out over time. However, regular maintenance can catch minor issues before they escalate into major problems.

For instance, a dirty evaporator coil can lead to a frozen coil, which can cause the compressor to overheat and eventually fail.

Replacing a compressor can cost anywhere from $4,000 to $12,000, not to mention labor costs. These repairs are far more expensive than basic preventative maintenance.

Shortened Lifespan of Equipment

The lifespan of your air dome air conditioner can be significantly shortened without regular upkeep. With proper maintenance, these units can last anywhere from 15 to 20 years.

However, without it, you might be looking at a much shorter operational lifespan due to parts wear, corrosion, and failures.

Replacing an air conditioning system can be an investment of $50,000 or more for a large commercial unit, making it critical to preserve your existing system as long as possible.

Downtime and Business Disruption

When the air conditioning system fails, you could face unexpected downtime, especially in facilities that depend on consistent temperature control.

In industries like sports, events, or storage, this can cause disruptions to operations, cancel events, or damage sensitive inventory.

These types of operational hiccups are costly not just in lost revenue, but in client trust and reputation. What’s worse, emergency repairs and expedited shipping of parts come with a hefty price tag.

Warranty Voidance

Most manufacturers require routine maintenance to keep warranties valid.

Failure to maintain your system according to the manufacturer’s guidelines can void your warranty, meaning that any repairs or parts replacements may be at your own expense.

A single compressor failure could then turn into a financial burden that could’ve been avoided with a simple maintenance checklist.

2. Step-by-Step Air Dome AC Maintenance Guide

Routine maintenance is key to keeping your air dome air conditioner running efficiently. Following a structured, systematic approach ensures that all aspects of the system are regularly checked and serviced.

Here’s a breakdown of daily, monthly, quarterly, and annual maintenance tasks to ensure your unit stays in top shape.

Daily Maintenance

Daily maintenance should be part of the routine operational checks. These tasks can usually be performed by in-house staff or facility management.

- Inspect Control Panel: Check the control panel to ensure that the thermostat is set to the desired temperature and that the system is running smoothly. Ensure the air pressure is stable and within the specified range.

- Listen for Unusual Sounds: Hissing or grinding noises may indicate issues with the compressor or internal components. Pay attention to abnormal sounds and address them promptly.

- Check Airflow: Walk around the space and make sure the diffusers are not obstructed by equipment, debris, or dust. Any blockage can affect airflow and cooling efficiency.

- Monitor Humidity Levels: Use a hygrometer to ensure that the relative humidity is maintained within the optimal range of 40–60%. If humidity is too high or low, it can affect the air quality and the system’s efficiency.

Monthly Maintenance

A professional technician or qualified maintenance team should handle monthly maintenance tasks. These checks are essential for keeping the unit running at peak performance.

- Replace or Clean Filters: Filters should be checked and replaced every month or when airflow is restricted. Dirty filters force the system to work harder and can lead to reduced performance.

- Inspect Dome Pressure: Ensure the dome pressure is consistent and meets the required specifications. Fluctuations may indicate a problem with the air dome’s structure or pressure system.

- Clean Condensate Lines: Blocked condensate lines can cause water overflow, leading to water damage. Clean them monthly to ensure there is no buildup of debris.

- Check Refrigerant Level: Inspect the refrigerant sight glass. If you see bubbles, it may be a sign that the refrigerant level is too low and needs to be replenished.

Quarterly Maintenance

Quarterly checks should involve a more detailed inspection, often requiring a qualified technician. This is where you start looking at the long-term health of the system.

- Clean Coils: Both the condenser and evaporator coils should be cleaned at least every three months. Dirt on the coils can reduce heat exchange efficiency and force the unit to consume more power.

- Lubricate Motors: Motors, especially those connected to the blower fan, need to be lubricated to prevent excessive wear. Over time, lubrication helps the motor run smoothly and prevents premature failure.

- Check Electrical Components: Inspect all electrical components for signs of wear. Tighten any loose connections and test the capacitors, wiring, and control panel to ensure everything is in good working order.

- Verify System Calibration: Ensure the thermostats, sensors, and pressure controllers are calibrated properly. Misaligned sensors can cause the system to work inefficiently, leading to overcooling or undercooling.

Annual Maintenance

Annual maintenance should be comprehensive and may require a full inspection by an HVAC professional. These checks are the foundation for keeping the unit in optimal condition for the long run.

- Full Refrigerant System Check: Ensure the refrigerant is at the correct levels, and perform a leak test to identify any potential issues. Low refrigerant levels can cause the system to freeze up or overheat, leading to severe damage.

- Inspect Ducts: Check the ductwork for leaks or damage. Duct leaks can reduce airflow and increase energy consumption.

- Evaluate Backup Systems: Air dome air conditioners often rely on backup systems, such as pressure stabilizers and emergency generators. Test these systems to ensure they’re functioning correctly in case of a power failure.

- Perform System Performance Analysis: Review system logs and operational data to identify areas where energy efficiency can be improved. Analyze the system’s cooling capacity and compare it to the manufacturer’s specifications.

3. Tools and Resources You’ll Need

Having the right tools for maintenance can make a significant difference in ensuring the system stays in peak condition. These tools are necessary for monitoring, adjusting, and troubleshooting your air dome air conditioner.

Essential Tools

- Digital Multimeter: A multimeter is crucial for diagnosing electrical issues such as voltage drops, circuit failures, and faulty connections.

- Manometer: This device is used to measure the pressure within the air dome and the HVAC system, ensuring that all components are operating at the correct pressure.

- Refrigerant Gauges: These gauges are used to check refrigerant pressure levels and make sure the refrigerant charge is appropriate. This is essential for maintaining cooling efficiency.

- Coil Cleaner Solution: Special cleaning solutions are needed to clean the evaporator and condenser coils. Coils that are clogged with dirt or debris can reduce heat exchange efficiency.

- Thermometer: An infrared thermometer is useful for checking surface temperatures to ensure that heat is being exchanged properly.

- Lubrication Equipment: For motors and fans, lubrication helps reduce friction and wear. Proper lubrication prevents failure and ensures smooth operation.

- Hygrometer: This is essential for monitoring humidity levels within the dome. It ensures that your air conditioner is maintaining the correct relative humidity for optimal comfort.

Other Resources

- CMMS Software: A Computerized Maintenance Management System (CMMS) allows you to track maintenance schedules, logs, and reports. This software helps you keep a historical record of maintenance activities, ensuring that you stay on top of service needs.

- Manufacturer Manuals: Always refer to the manufacturer’s guidelines and technical documentation for specific maintenance schedules and procedures for your air dome air conditioner.

4. Common Mistakes to Avoid

Even the most experienced facility managers can fall into traps when it comes to maintaining air dome air conditioners. Below are the most common mistakes to avoid in order to keep your system running smoothly.

Using Incorrect Filters

Not all filters are created equal. Using filters that don’t meet the specifications can reduce airflow and increase energy costs. Always use the right size and MERV (Minimum Efficiency Reporting Value) rating based on manufacturer recommendations.

Ignoring Pressure Fluctuations

Pressure is one of the most critical factors in an air dome air conditioner. Ignoring pressure fluctuations can lead to structural issues or system overloads. If you notice any sudden or irregular pressure changes, investigate the issue immediately.

Failing to Lubricate Motors

Skipping the lubrication of motors and moving parts is a mistake that can lead to severe damage. Over time, friction can wear down parts, causing them to fail prematurely. Regular lubrication is essential to prevent this from happening.

Overcharging the Refrigerant

It’s tempting to think that more refrigerant means better cooling, but overcharging can actually damage the system. Always ensure that refrigerant levels are properly measured and maintained within manufacturer specifications.

Overlooking Emergency Systems

Backup power systems, pressure regulators, and emergency alarms should not be ignored. If these systems fail during an emergency, you could experience a complete shutdown of the air dome. Perform regular checks to ensure these systems are operational.

5. Signs Your System Needs Immediate Attention

Sometimes, the signs that your air dome air conditioner needs immediate attention are obvious, but other times, the issues develop slowly over time. Here’s a list of common red flags to watch for:

Cooling Performance Drops

If the system suddenly fails to maintain the set temperature, especially during peak heat, it’s a sign that something’s wrong. Possible causes include dirty coils, low refrigerant, or sensor malfunctions.

Dome Pressure Fluctuations

Any significant change in dome pressure can cause structural integrity issues or indicate a malfunction in the air pressurization system.

Unusual Sounds

Squealing, grinding, or rattling noises could indicate worn-out bearings, motor issues, or something stuck in the fan blades. These sounds require immediate attention to avoid further damage.

Water Leaks

If you notice water pooling around the unit or inside the ducts, it could be due to blocked condensate lines or a frozen coil. Left unchecked, this can cause serious water damage.

Strange Odors

If your system begins emitting a burnt or musty smell, it might indicate overheating components or mold growth inside the ductwork.

Conclusion

Regular maintenance of your air dome air conditioner is not just about preserving the system’s efficiency it’s about ensuring long-term savings, avoiding costly repairs, and preventing unexpected disruptions.

By following a structured maintenance schedule, you can maximize energy efficiency, reduce operating costs, and extend the lifespan of your equipment.

It’s easy to overlook the small tasks, but the real cost of neglecting these steps can be much higher in terms of both time and money.

From cleaning filters and inspecting coils to monitoring pressure levels and checking refrigerant levels, each task plays a crucial role in keeping your system running smoothly.

Avoiding common mistakes like using incorrect filters or skipping lubrication will also protect the overall performance of your unit.

Remember, a well-maintained air dome air conditioner not only ensures optimal comfort and pressure regulation for your facility, but it also contributes to the overall success of your operations.

Stay on top of maintenance, use the right tools, and address issues before they escalate.

With proactive care, you can count on your system to work reliably when you need it most, saving you from costly breakdowns and system failures.