Airplane pre-conditioning air unit cooling is a critical part of modern airport ground operations, ensuring that aircraft cabins are properly cooled before boarding and during on-ground servicing. For airlines, airports, and ground handling teams, reliable pre-conditioned air (PCA) supply directly affects passenger comfort, aircraft turnaround efficiency, and overall operational cost control.

Unlike onboard systems that rely on the auxiliary power unit (APU), ground-based air conditioning units deliver stable, controlled airflow to the aircraft while it is parked at the gate or remote stand, reducing fuel burn, noise, and emissions.

As global aviation continues to focus on sustainability and faster gate operations, aircraft pre-conditioning systems are becoming standard equipment in both large international hubs and regional airports. These systems support the aircraft environmental control system by maintaining target cabin temperature, stabilizing humidity, and protecting sensitive onboard equipment during ground servicing.

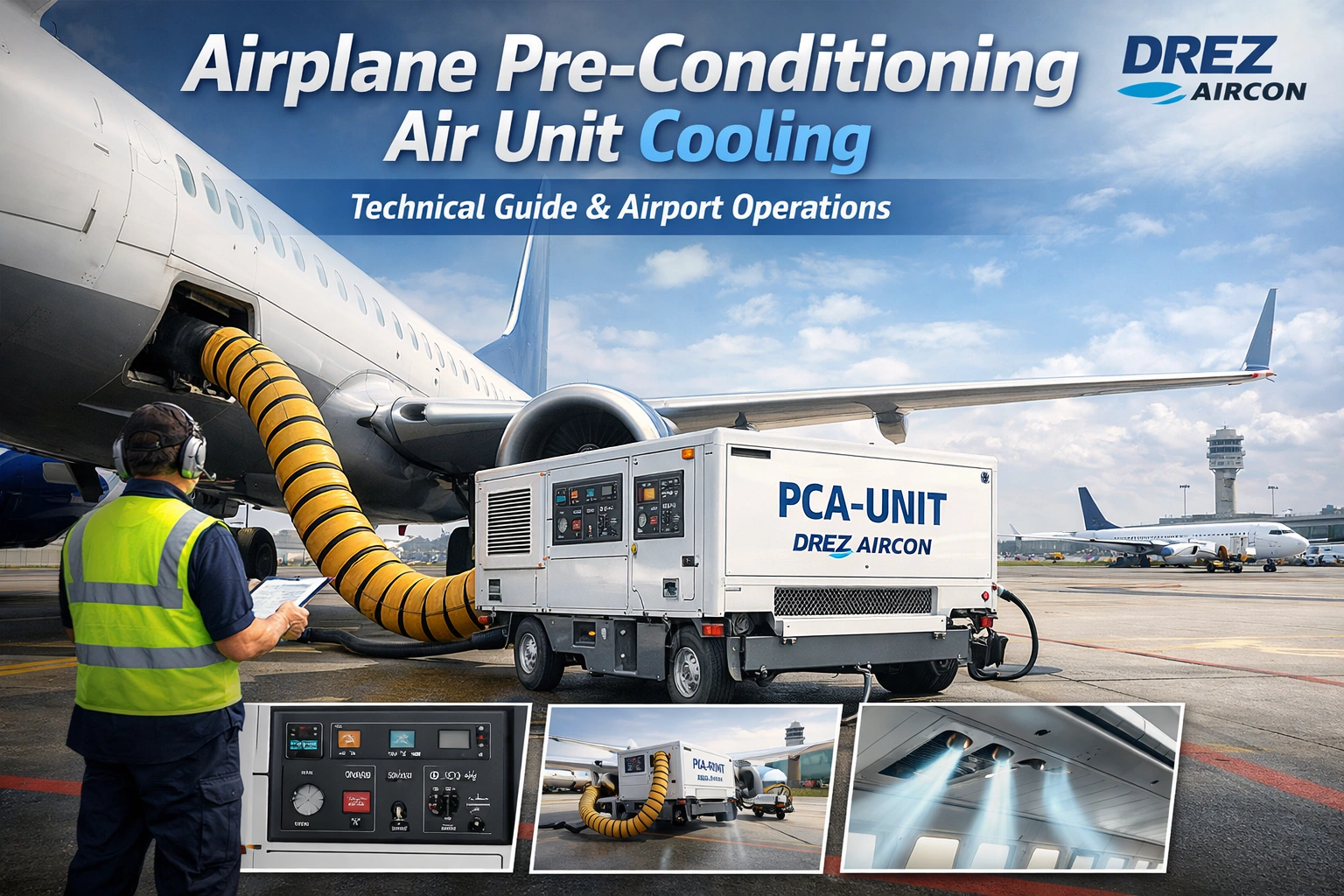

From portable aircraft cooling units to fixed jet bridge installations and mobile trailer-based solutions, today’s aviation ground cooling solutions are designed to adapt to different aircraft types, operational layouts, and climate conditions.

For airport operators and airlines, selecting the right ground-based air conditioning unit requires a clear understanding of cooling capacity, airflow performance, integration with existing ground support equipment, and long-term maintenance requirements.

More importantly, well-designed pre-conditioning systems contribute directly to improved aircraft turnaround time efficiency and better coordination between airport ground services.

Airplane Pre-Conditioning Air Unit Cooling: Technical Insights and Operational Advantages

Aircraft pre-conditioning air units (PCUs) play a crucial role in modern aviation operations. They are essential for maintaining cabin comfort, ensuring operational efficiency, and minimizing turnaround times at airports. As airlines and airport operators seek reliable, energy-efficient, and effective ground support equipment, understanding the technical functioning and operational advantages of these cooling systems becomes vital. This article provides a comprehensive overview of airplane pre-conditioning air unit cooling, combining technical insights, operational benefits, and practical considerations relevant to aviation professionals.

1. Introduction

Airplane pre-conditioning air unit cooling systems are designed to regulate cabin temperature and environmental conditions before passengers board. Ground-based pre-conditioning units, often referred to as portable aircraft cooling units, supply cooled or heated air directly to the aircraft while it is parked at the gate or apron.

Efficient PCU operation improves passenger comfort, reduces reliance on onboard auxiliary power units (APUs), and enhances the overall efficiency of ground operations. Airlines benefit from faster aircraft turnaround, energy savings, and reduced emissions, while airports gain from smoother logistical management of ground services.

2. What is an Airplane Pre-Conditioning Air Unit?

A pre-conditioning air unit is a piece of ground support equipment (GSE) that conditions aircraft cabins while planes are parked on the ground. These units provide temperature-controlled air to maintain comfortable cabin conditions regardless of outside weather.

Components of a Typical PCU:

- Compressor and cooling system: Provides cold air to the aircraft.

- Heater or heat exchanger: Supplies warm air during colder climates.

- Fan system and ducting: Distributes air through hoses connected to the aircraft air inlets.

- Control panel: Allows operators to adjust temperature and airflow according to aircraft requirements.

PCUs integrate closely with an aircraft’s environmental control system (ECS), supporting onboard systems while minimizing the use of APUs, which consume fuel and generate noise and emissions.

3. How Airplane Pre-Conditioning Air Unit Cooling Works

The operation of a PCU begins with its connection to the aircraft via a flexible duct, typically attached near the jet bridge or aircraft fuselage. The unit draws ambient air, conditions it through its cooling and heating components, and delivers it into the aircraft cabin.

Key Processes:

- Air Intake: Ambient air is drawn into the unit.

- Conditioning: Air passes through the refrigeration or heat exchanger system, reaching the desired temperature.

- Air Delivery: Conditioned air is pumped into the aircraft cabin, maintaining comfort while aircraft systems are powered down.

- Monitoring: Sensors and control panels ensure temperature consistency and operational safety.

Types of PCUs:

- Portable units: Small, flexible units used for a variety of aircraft sizes and gate locations.

- Fixed units: Installed at gates or remote stands for permanent service.

- Mobile trailer units: Larger units capable of servicing wide-body aircraft and remote aprons.

4. Operational Advantages of PCU Cooling Systems

Aircraft pre-conditioning air unit cooling systems provide multiple benefits that directly impact airline efficiency and passenger experience.

4.1 Passenger Comfort

Maintaining a controlled cabin temperature before boarding ensures passengers enter a comfortable environment, reducing complaints and enhancing airline reputation.

4.2 Reduced Fuel Consumption and Emissions

Using PCUs reduces reliance on aircraft APUs, which burn jet fuel and produce CO₂ emissions. Airports with large fleets benefit from lower overall emissions, supporting sustainability initiatives.

Example: At a European airport, deploying PCUs for a fleet of 50 narrow-body aircraft reduced fuel usage by approximately 150 liters per aircraft per day, translating into significant operational cost savings.

4.3 Faster Aircraft Turnaround Time

By pre-conditioning the cabin before boarding, airlines can speed up boarding procedures and minimize delays caused by passenger discomfort or delayed system startup.

4.4 Operational Flexibility

PCUs allow airlines to service aircraft at remote stands without the need for extensive onboard power usage, making them ideal for airports with limited gate availability.

5. Key Considerations for Airport and Airline Operators

Selecting the right PCU for ground operations requires a detailed assessment of operational requirements:

- Sizing and Capacity: The cooling capacity should match the aircraft size (narrow-body vs wide-body) and expected passenger load.

- Integration: Units must integrate with aircraft ECS without interfering with other systems.

- Maintenance: Regular servicing ensures reliability and prevents downtime during peak operations.

- Safety Compliance: Ground operators must adhere to airport safety protocols, including noise, emissions, and electrical standards.

6. Common Challenges and Solutions

Despite their advantages, PCUs face operational challenges:

6.1 Extreme Weather Conditions

High ambient temperatures or cold extremes can reduce cooling or heating efficiency. High-capacity units and proper maintenance mitigate these effects.

6.2 Logistics and Placement

Large airports with multiple gates require efficient deployment strategies to ensure all aircraft have access to PCUs without obstructing ground traffic.

6.3 Equipment Downtime

Units can experience mechanical or electrical failures. Implementing preventive maintenance and monitoring helps reduce the risk of operational delays.

7. Case Study: Real-World Application

At Drez Aircon, ground-based air-conditioning units have been deployed for a mid-sized international airport servicing narrow and wide-body aircraft.

Scenario:

- 20 aircraft per day required pre-conditioning.

- Ambient temperature: 35–40°C.

- PCUs delivered cooled air directly to aircraft cabins, reducing onboard APU usage by 80%.

- Operational benefits: Reduced turnaround times by 15–20 minutes per aircraft, fuel savings of ~120 liters per aircraft, and improved passenger satisfaction scores.

This case illustrates how effective airplane pre-conditioning air unit cooling can contribute to both operational efficiency and cost savings.

8. Future Trends in Aircraft Ground Cooling

The aviation industry is exploring innovations in pre-conditioning air units:

- Energy-efficient systems: Low-power compressors and hybrid units reduce energy consumption.

- Automation: Smart temperature sensors and AI-based airflow management optimize performance.

- Sustainability: Integration with renewable energy sources and reduced greenhouse gas emissions.

- Mobile solutions: Enhanced trailer and portable units allow greater flexibility at remote aprons.

These trends are shaping the future of ground support, emphasizing efficiency, environmental responsibility, and operational reliability.

FAQS

1. What is airplane pre-conditioning air unit cooling?

Airplane pre-conditioning air unit cooling is a ground-based air conditioning process that supplies cooled or heated air to an aircraft cabin while the aircraft is parked on the apron or at the gate. The system uses pre-conditioned air (PCA) units to support the aircraft environmental control system without running the onboard auxiliary power unit.

2. How does a pre-conditioned air (PCA) unit connect to an aircraft?

A PCA unit connects to the aircraft through a flexible insulated hose that is attached to the aircraft’s ground air inlet port. The ground-based air conditioning unit then delivers controlled airflow directly into the cabin distribution system.

3. Why is airplane pre-conditioning air unit cooling important for aircraft turnaround time efficiency?

Pre-conditioning the cabin before boarding allows the aircraft to reach target temperature faster, which reduces preparation time at the gate. This improves aircraft turnaround time efficiency and helps airlines maintain tighter flight schedules.

4. What types of aircraft can be supported by aircraft pre-conditioning systems?

Modern aircraft pre-conditioning systems can serve narrow-body, wide-body, and regional aircraft. System capacity is selected based on cabin volume, required airflow rate, and cooling load for each aircraft type.

5. What is the difference between portable aircraft cooling units and fixed PCA systems?

Portable aircraft cooling units are mobile and can be moved between aircraft stands, while fixed PCA systems are permanently installed at gates or jet bridges. Both provide airplane cabin cooling, but fixed systems are typically used for high-traffic terminal operations.

6. How does airplane pre-conditioning air unit cooling reduce fuel consumption?

By supplying ground-based cooling, the aircraft does not need to run its auxiliary power unit for cabin air. This directly reduces fuel burn, operating costs, and emissions during ground operations.

7. How does airplane pre-conditioning air unit cooling integrate with the aircraft environmental control system?

The conditioned air supplied by the PCA unit enters the aircraft environmental control system through the ground air inlet. The onboard system distributes the air throughout the cabin in the same way it would when the aircraft is powered normally.

8. What are the main technical requirements when selecting a ground-based air conditioning unit for aircraft?

Key requirements include cooling capacity, airflow volume, hose compatibility, electrical power availability, noise limits, and compliance with airport ground services and aircraft manufacturer standards.

9. What maintenance is required for aircraft ground cooling solutions?

Routine maintenance includes filter replacement, compressor inspection, electrical checks, airflow testing, and verification of temperature control accuracy. Proper maintenance ensures reliable aviation ground cooling solutions and minimizes operational downtime.

10. Can airplane pre-conditioning air unit cooling be used at remote stands without jet bridges?

Yes. Mobile and trailer-mounted ground-based air conditioning units are commonly used at remote stands and apron positions where jet bridge air conditioning systems are not available. These mobile solutions provide full aircraft pre-conditioning capability for ground support operations.

9. Conclusion

Airplane pre-conditioning air unit cooling systems are critical for modern aviation operations. They provide essential technical functionality, operational efficiency, and passenger comfort while reducing fuel consumption and emissions. By understanding the design, operation, and benefits of PCUs, airlines and airport operators can optimize ground operations and ensure a high standard of service.

Deploying professional-grade PCUs, such as those designed by Drez Aircon, ensures reliable performance, operational flexibility, and measurable cost savings, making them a vital component of modern airport infrastructure.