Airplane Pre-Conditioning Air Unit Service is a critical aspect of aircraft ground operations, ensuring that cabin environments remain comfortable and safe while the aircraft is on the tarmac. Pre-conditioning air (PCA) units supply regulated temperature and humidity, maintaining optimal conditions for passengers and crew before boarding.

These systems are essential not only for comfort but also for operational efficiency, preventing unnecessary strain on the aircraft’s environmental control system (ECS) and avoiding delays caused by equipment failure.

Regular maintenance of PCA units is crucial, as these systems operate under demanding conditions and are exposed to factors such as dust, moisture, and temperature fluctuations. Common issues like reduced airflow, refrigerant leaks, or electrical malfunctions can lead to compromised cabin conditions and increased downtime.

Addressing these problems proactively through preventive maintenance and professional servicing ensures reliable operation and extends the lifespan of the equipment.

In addition, proper airplane pre-conditioning air unit service enhances energy efficiency, reduces operational costs, and ensures compliance with aviation safety standards. For airlines, airport operators, and maintenance engineers, understanding the key aspects of PCA unit care is essential for smooth operations.

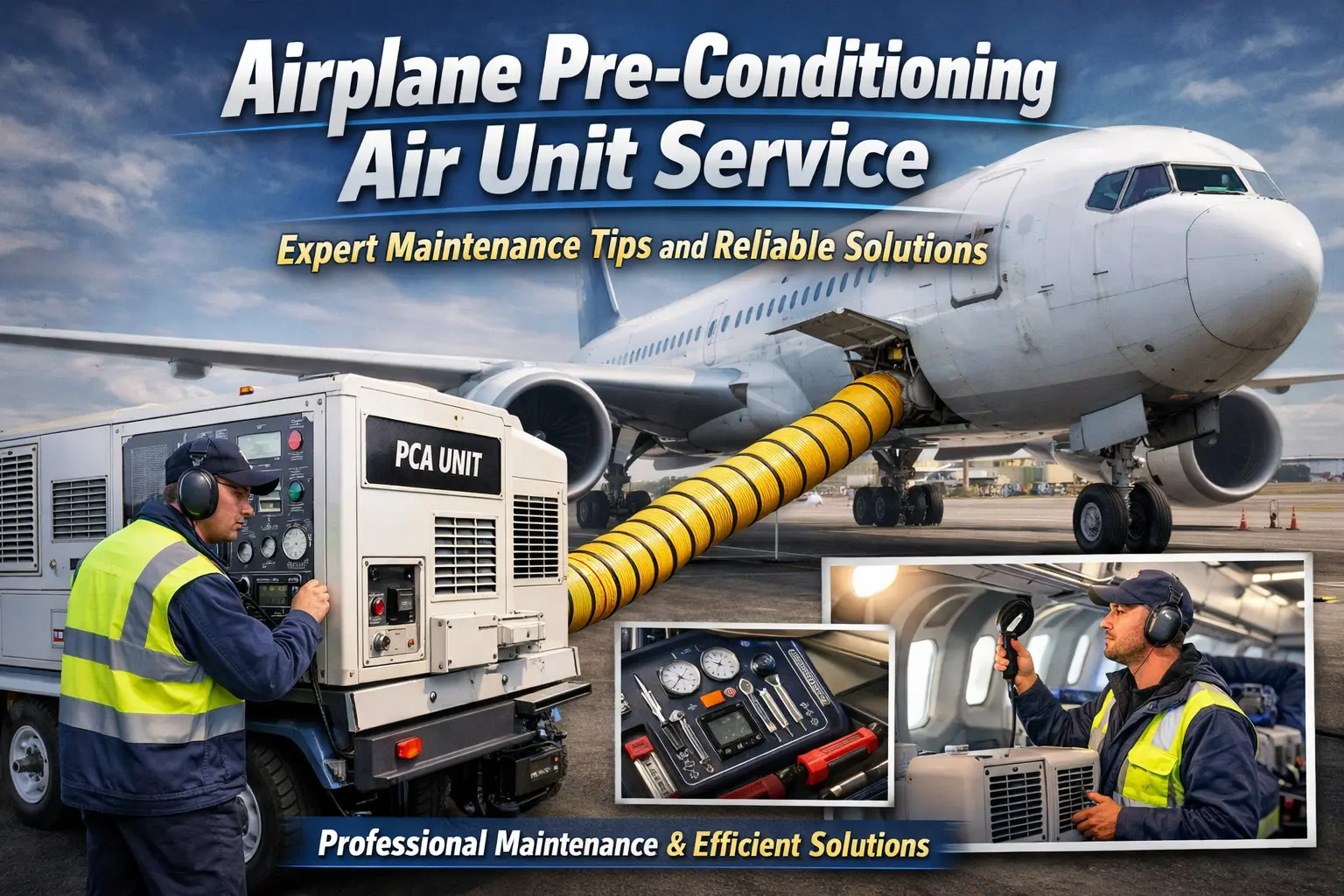

Airplane Pre-Conditioning Air Unit Service: Expert Maintenance Tips and Reliable Solutions

In this guide, we will explain expert maintenance tips, reliable solutions, and best practices for airplane pre-conditioning air unit service.

1. Introduction

Airplane pre-conditioning air (PCA) units play a critical role in maintaining cabin comfort, safety, and operational efficiency. These units supply pre-conditioned air from ground support systems or onboard units to ensure the aircraft environment remains within optimal temperature and humidity ranges.

For airline operators, maintaining PCA units is not just about passenger comfort it directly impacts operational schedules, fuel efficiency, and compliance with aviation safety standards. Ignoring regular maintenance can lead to costly repairs, system failures, and increased downtime at airports.

Professional PCA unit service ensures that aircraft environmental control systems (ECS) function reliably, meeting both operational and regulatory requirements. Reliable maintenance also prevents unexpected HVAC failures during boarding, taxiing, or flight preparation, which can delay departures.

This guide provides expert maintenance tips, practical solutions, and a detailed overview of PCA unit service designed for airline operators, maintenance engineers, and airport service providers.

2. Understanding Airplane Pre-Conditioning Air Units

What is a Pre-Conditioned Air System?

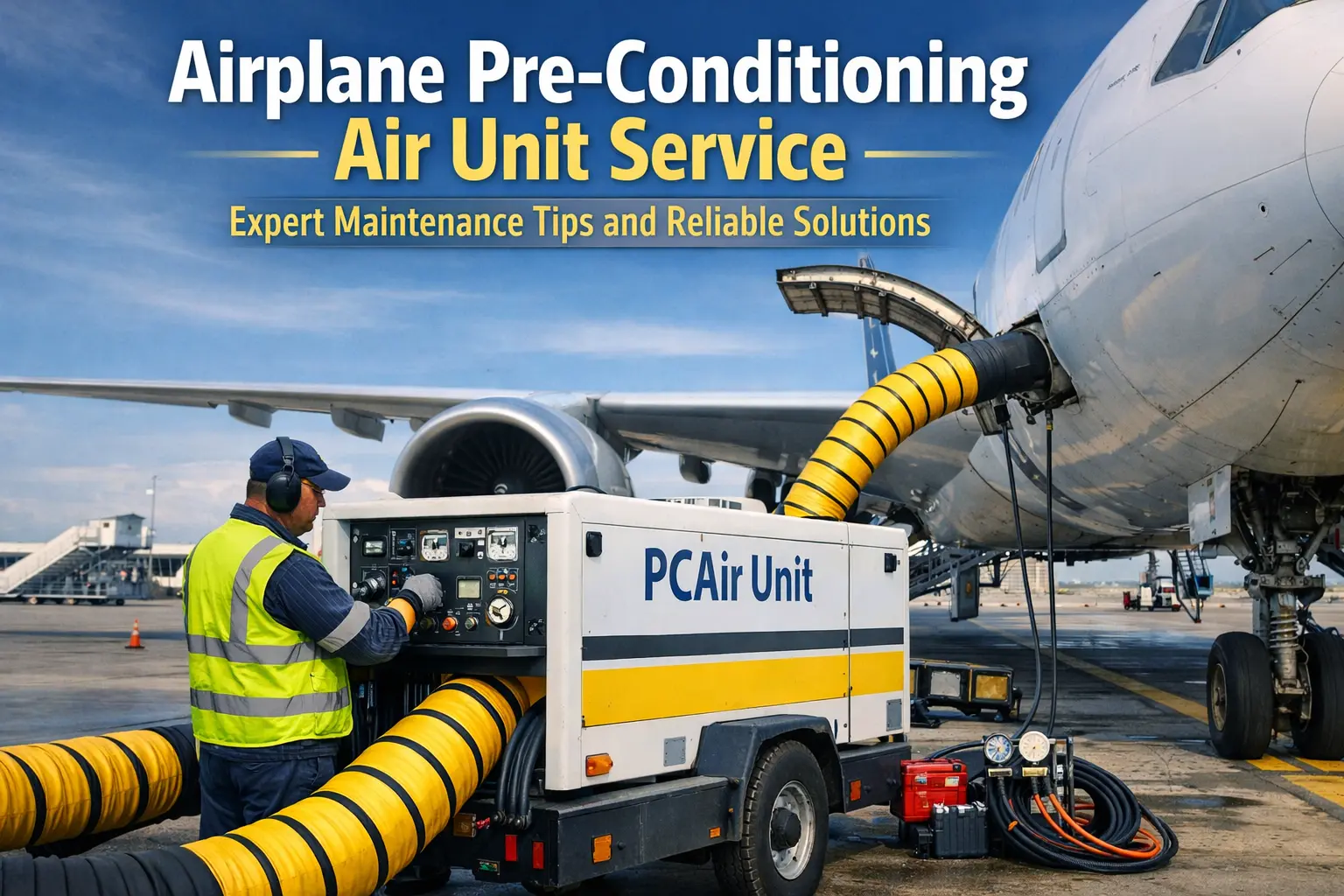

A pre-conditioned air system provides cooled or heated air to an aircraft while it is on the ground. It is commonly connected to ground-based PCA units at the gate or uses onboard auxiliary power units (APUs). PCA units regulate temperature and humidity in the cabin, cockpit, and cargo areas, allowing boarding and maintenance procedures to continue under controlled conditions.

Key Components of an Aircraft PCA Unit

A typical PCA unit includes:

- Compressor – Pressurizes refrigerant to circulate cooling.

- Evaporator and Condenser Coils – Exchange heat to cool or heat the supplied air.

- Blower Fans – Distribute conditioned air to the aircraft air supply lines.

- Control Panel and Sensors – Monitor temperature, airflow, and pressure.

- Ducting and Hoses – Connect the PCA unit to aircraft air inlets.

Proper understanding of these components helps in targeted maintenance and troubleshooting.

Differences Between PCA Units for Different Aircraft Types

Aircraft size, passenger capacity, and environmental control system complexity determine PCA unit requirements. For example:

- Narrow-body aircraft often require smaller, portable PCA units with basic airflow control.

- Wide-body aircraft demand higher-capacity units capable of delivering precise temperature and humidity regulation.

- Business jets and private aircraft may utilize compact or customized PCA units tailored for onboard comfort.

3. Common Issues in PCA Units

Understanding common issues helps airlines proactively manage their PCA units, minimizing downtime and repair costs.

Airflow and Cooling/Heating Inefficiencies

- Cause: Blocked filters, fan malfunctions, or duct leaks.

- Impact: Uneven cabin temperature, discomfort during boarding, and additional load on the aircraft ECS.

- Solution: Regular inspection of airflow paths and immediate filter replacement.

Leaks and Refrigerant Issues

- Cause: Aging hoses, compressor seals, or condenser cracks.

- Impact: Reduced cooling efficiency, increased energy consumption, and potential damage to compressors.

- Solution: Leak detection using pressure gauges or refrigerant sensors, followed by prompt sealing or component replacement.

Electrical and Control System Failures

- Cause: Faulty wiring, sensor failure, or control panel errors.

- Impact: Uncontrolled temperature, failure of automated functions, or complete unit shutdown.

- Solution: Routine inspection, calibration, and replacement of damaged sensors or wiring.

Signs Your Airplane PCA Unit Needs Service

- Inconsistent cabin temperature during pre-flight operations.

- Reduced airflow or weak cooling performance.

- Unusual noises from compressors or blowers.

- Frequent tripping of unit safety mechanisms.

4. Expert Maintenance Tips for PCA Units

Proper maintenance ensures that PCA units deliver consistent performance and reduces the risk of costly downtime.

Routine Inspection and Preventive Maintenance

- Check the unit for corrosion, damage, and loose connections.

- Inspect all hoses, ducting, and joints for leaks or wear.

- Test fan and compressor operation under load conditions.

Cleaning and Replacing Filters

- Dirty filters reduce airflow and increase strain on the system.

- Replace air filters according to manufacturer recommendations or more frequently in dusty environments.

- Clean evaporator and condenser coils to improve heat exchange efficiency.

Checking Refrigerant Levels and Airflow Performance

- Low refrigerant reduces cooling capacity and efficiency.

- Monitor refrigerant pressure and top-up using certified aviation-grade refrigerants.

- Use anemometers to measure airflow and adjust blower speed if needed.

Troubleshooting Common HVAC System Problems

- Identify unusual sounds and vibration patterns from fans or compressors.

- Check for electrical faults using multimeters and circuit testers.

- Test control sensors and recalibrate as necessary to maintain precise temperature regulation.

5. Reliable Solutions for PCA Unit Service

PCA unit service can be handled either on-site at the airport or in a dedicated maintenance workshop depending on the complexity of the issue.

On-Site Repair vs. Workshop Servicing

- On-Site: Quick fixes for minor leaks, filter replacements, and sensor calibrations. Reduces aircraft ground time.

- Workshop: Detailed inspections, major component replacement, and comprehensive testing before returning the unit to service.

Component Replacement and Upgrades

- Replace worn compressors, fans, or control units to ensure operational reliability.

- Upgrade outdated PCA units to improve cooling efficiency and reduce energy consumption.

Portable and Temporary Aircraft Air Conditioning Solutions

- For airports or operators without permanent PCA installations, portable PCA units provide flexible, reliable cooling solutions.

- DrezAircon specializes in providing custom portable and industrial air-conditioning systems suitable for aircraft ground support.

Working with Certified Aviation HVAC Service Providers

- Certified service ensures compliance with aviation safety regulations.

- Experienced technicians reduce repair errors and extend the lifespan of PCA units.

- Providers like DrezAircon deliver maintenance, installation, and replacement services tailored to airline and airport operational requirements.

6. Benefits of Professional PCA Unit Maintenance

Maintaining PCA units is not only about comfort; it has measurable operational and economic benefits.

Ensuring Passenger Comfort and Safety

- Consistent cabin temperature during boarding reduces passenger complaints.

- Properly maintained units prevent condensation and humidity-related equipment issues.

Reducing Downtime and Operational Delays

- Routine maintenance reduces the risk of in-service failures.

- Efficient PCA units ensure on-time departures, minimizing airport delays.

Extending Equipment Lifespan

- Regular inspections and preventive maintenance extend the life of compressors, fans, and control systems.

- Reduces frequency of costly component replacements.

Cost Efficiency Over Time

- Preventive maintenance reduces expensive emergency repairs.

- Optimized airflow and refrigerant usage lower operational energy costs.

7. Choosing the Right PCA Unit Service Provider

Selecting a reliable service provider is crucial for maintaining aircraft pre-conditioning air units effectively.

Factors to Consider

- Experience and technical expertise in aviation HVAC systems.

- Certification and compliance with aviation safety standards.

- Global support and fast response for urgent repairs.

- Proven track record with commercial airlines and airport operators.

Why DrezAircon is an Ideal Choice

DrezAircon specializes in portable and industrial air-conditioning solutions, including airplane pre-conditioning air units. Their services include:

- Routine maintenance and preventive checks

- Component replacement and system upgrades

- Custom solutions for temporary or permanent installations

- Global support and professional installation

With expertise in industrial and aviation HVAC systems, DrezAircon ensures reliable and efficient PCA unit service, helping airlines and airports maintain operational efficiency.

10 FAQs

- What is an airplane pre-conditioning air unit (PCA unit)?

A PCA unit is a system that supplies pre-conditioned air to an aircraft on the ground, regulating temperature and humidity in the cabin, cockpit, and cargo areas. It ensures passenger comfort and reduces strain on the aircraft’s environmental control system (ECS). - Why is PCA unit maintenance important for aircraft operations?

Regular maintenance prevents system failures, ensures consistent cabin comfort, reduces downtime, and minimizes operational delays caused by inefficient or faulty units. - What are the common problems encountered in PCA units?

Common issues include airflow inefficiencies, refrigerant leaks, electrical malfunctions, fan or compressor wear, and sensor failures. - How often should airplane PCA units be serviced?

PCA units should undergo routine inspections at least quarterly, with preventive maintenance performed as recommended by the manufacturer or based on operational hours. - What are the benefits of using professional PCA unit service providers?

Certified providers ensure compliance with aviation standards, perform precise troubleshooting, replace worn components, and provide expert guidance for long-term efficiency. - Can PCA units be repaired on-site at the airport?

Yes. Minor repairs like filter replacement, sensor calibration, and refrigerant top-ups can be performed on-site, reducing aircraft ground time. - What components are critical to PCA unit performance?

Key components include compressors, evaporator and condenser coils, blower fans, ducting, and control sensors. Proper maintenance of each ensures reliable operation. - Are there portable PCA solutions for airports without permanent units?

Yes. Portable PCA units provide flexible cooling and heating solutions for temporary operations, charter flights, or airports with limited infrastructure. - How does proper PCA unit maintenance affect operational costs?

Preventive maintenance reduces emergency repairs, improves energy efficiency, and extends equipment lifespan, resulting in lower long-term operational costs. - Why choose DrezAircon for airplane PCA unit services?

DrezAircon specializes in aviation and industrial HVAC systems, offering expert maintenance, installation, and custom solutions that ensure reliable pre-conditioned air supply for all aircraft types.

Summary

Airplane pre-conditioning air units are essential for operational efficiency, passenger comfort, and safety. Proper maintenance, routine inspections, and expert servicing prevent failures and extend the lifespan of these critical systems.

By following structured maintenance tips, implementing preventive solutions, and choosing certified service providers, airline operators can ensure that their PCA units perform reliably under all operational conditions.

For airlines and airport operators looking for trusted PCA unit service, DrezAircon offers expert solutions, installation support, and reliable maintenance for both portable and permanent systems. Regular servicing ensures optimal cabin comfort, reduced downtime, and cost-effective operations.

Call to Action: Contact DrezAircon today to schedule professional airplane pre-conditioning air unit maintenance and ensure your aircraft’s environmental control systems operate at peak performance.