Factory air conditioner refrigerator systems play a critical role in maintaining optimal temperature control in industrial environments, from large manufacturing plants to expansive warehouse facilities. Unlike standard commercial air conditioners, these industrial AC and refrigeration units are designed to handle the unique challenges of factory settings, including high heat loads, large open floor areas, and temperature-sensitive production processes.

Investing in the right factory cooling equipment not only ensures the comfort and safety of employees but also protects machinery, electronic components, and perishable goods from heat-related damage. Modern units come with features such as energy-efficient industrial AC systems, durable compressors, and advanced ventilation integration, making them essential for factories seeking reliable and high-capacity cooling solutions.

Additionally, temperature-controlled factory environments can improve productivity, reduce operational costs, and enhance overall plant efficiency. Selecting the right unit requires careful consideration of capacity, energy consumption, and system durability to meet the specific demands of each industrial application.

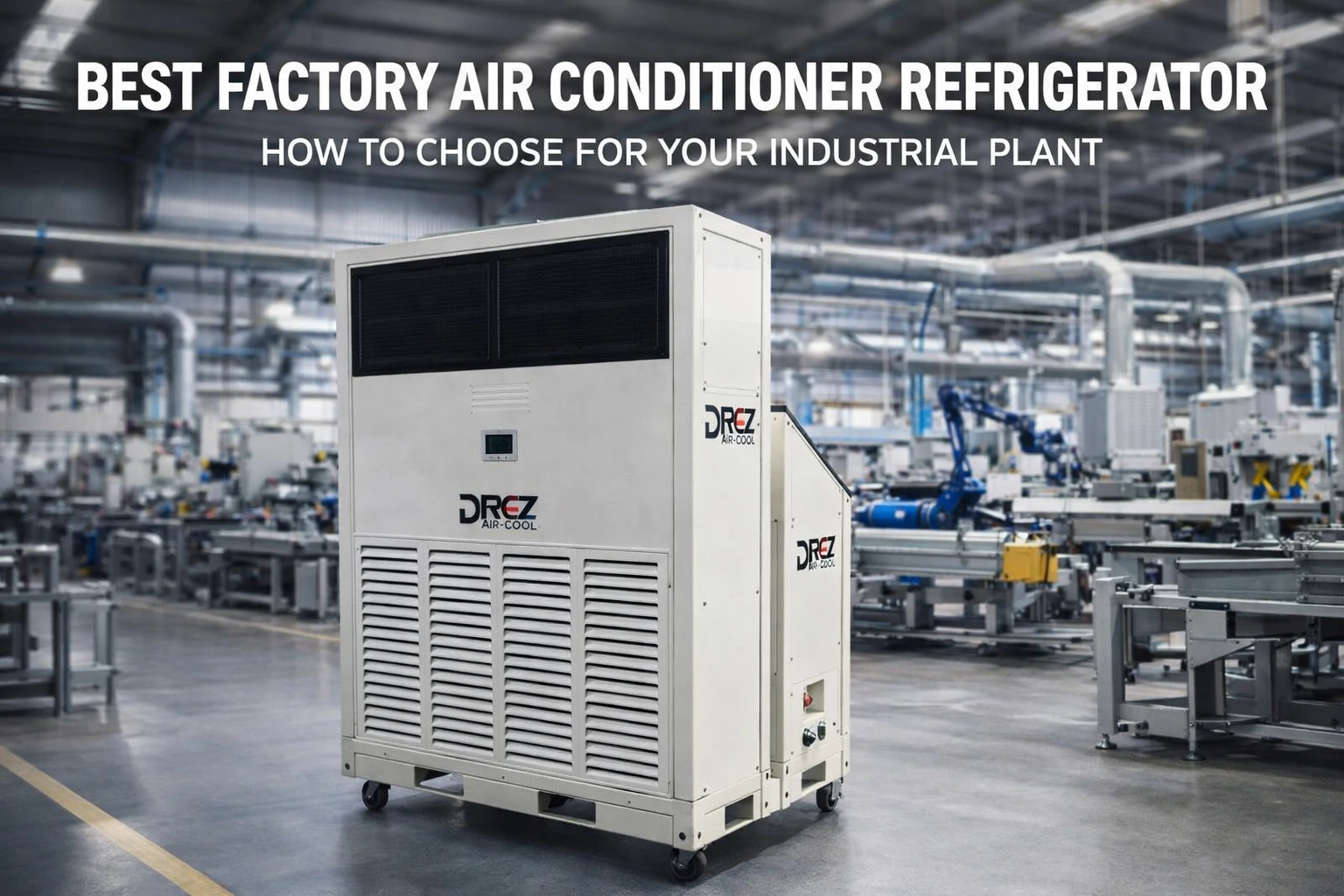

Best Factory Air Conditioner Refrigerator: How to Choose for Your Industrial Plant

In this guide, we will explain how to choose the best factory air conditioner refrigerator for your industrial plant, covering types, features, applications, and installation tips.

Factory air conditioner refrigerator systems are essential for modern industrial plants, warehouses, and manufacturing facilities. Unlike standard commercial air conditioning, these industrial units are designed to handle high heat loads, large open spaces, and sensitive production processes. A well-selected system ensures employee comfort, protects machinery, and maintains temperature-sensitive products, while also reducing operational costs through energy efficiency. Modern industrial AC and refrigeration solutions, such as those offered by Drez Aircon, integrate features like high-capacity cooling, durable compressors, advanced ventilation, and precise temperature control, making them indispensable for factory environments. Choosing the wrong system can lead to inefficiencies, equipment downtime, and loss of productivity. In this guide, we will explain how to select the best factory air conditioner refrigerator for your industrial plant, covering types, features, applications, installation, and maintenance.

What is a Factory Air Conditioner Refrigerator?

A factory air conditioner refrigerator is an industrial-grade cooling system designed to maintain stable temperatures in large-scale operations. Unlike residential or office AC units, these systems are built for high-capacity environments. They typically consist of:

- Compressors: Provide high-efficiency cooling power.

- Condensers: Release heat from the refrigerant.

- Evaporators: Absorb heat from the factory air.

- Fans & Ducts: Circulate air across production floors.

Industrial refrigeration units also differ in function; they provide cold storage solutions for perishable products or temperature-sensitive materials. Many factories combine industrial AC systems with refrigeration units to ensure uniform environmental conditions. This integration helps reduce energy consumption and maintain a safe, controlled workspace.

Types of Factory Air Conditioner Refrigerators

Selecting the right type depends on your factory’s size, application, and cooling requirements:

1. Portable Industrial AC Units

Portable units are ideal for temporary setups or smaller production areas. They offer flexibility, can be moved between different factory zones, and often feature modular ducting for directed airflow.

2. Packaged & Centralized Systems

These are fixed, high-capacity units for large manufacturing floors. Centralized systems offer even air distribution, high efficiency, and are suitable for factories with consistent temperature requirements.

3. Trailer-Mounted & Temporary Solutions

Trailer-mounted AC systems are designed for temporary or seasonal setups. They provide rapid deployment and are often used in industries with fluctuating production demands.

4. Refrigeration Units for Storage & Processing

Industrial refrigerators maintain strict temperature control for warehouses, food processing units, or chemical plants. These systems prevent spoilage and ensure product quality across production and storage stages.

Key Factors to Consider When Choosing a Factory AC Refrigerator

1. Factory Size & Cooling Capacity

The cooling capacity, usually measured in tons or kW, should match the factory’s volume. Undersized units lead to uneven cooling, while oversized units increase energy costs.

2. Temperature Requirements & Production Needs

Different processes require specific temperatures. For example, electronics manufacturing requires tightly controlled humidity and temperature, while food processing demands precise refrigeration.

3. Energy Efficiency

Modern industrial AC systems use high-efficiency compressors and eco-friendly refrigerants. Look for systems with EER or SEER ratings to reduce operational costs.

4. Durability & Noise Levels

Factories demand heavy-duty AC units that operate continuously. Durable compressors, corrosion-resistant materials, and low-noise fans ensure long-term reliability without disrupting operations.

5. Integration with Existing HVAC Systems

Compatibility with current ventilation or AC infrastructure can reduce installation costs and improve efficiency. Some Drez Aircon systems allow modular expansion for future factory upgrades.

Applications in Industrial Plants

- Production Floors: Maintaining a consistent environment improves worker safety and machinery performance.

- Warehouses & Storage: Proper refrigeration prevents spoilage and ensures materials are stored in optimal conditions.

- Sensitive Manufacturing Processes: Electronics, pharmaceuticals, and chemical plants rely on precision-controlled environments.

- Temporary Setups: Seasonal or project-based cooling can be deployed quickly with portable or trailer-mounted systems.

Case Study: A large electronics manufacturing plant in Guangzhou deployed Drez 32 Ton integrated AC systems across multiple production halls, achieving uniform temperature control while reducing energy costs by 15% over 12 months.

Installation & Maintenance Considerations

1. Installation Tips

- Place units for optimal airflow, avoiding obstructions.

- Ensure proper drainage for condensation to prevent water damage.

- Use modular ducting for flexible air distribution.

2. Maintenance

- Schedule routine filter cleaning and coil inspection.

- Monitor refrigerant levels and compressor performance.

- Preventive maintenance reduces downtime and prolongs equipment life.

3. Safety & Compliance

- Adhere to local HVAC and industrial safety regulations.

- Use certified refrigerants and electrical components to reduce risk of accidents.

Benefits of the Best Factory Air Conditioner Refrigerators

- Employee Comfort & Productivity: Stable temperatures reduce heat stress and improve concentration.

- Protection of Machinery: Temperature fluctuations can damage sensitive equipment.

- Energy Efficiency & Cost Savings: High-quality industrial units reduce energy bills over time.

- Temperature Control for Sensitive Products: Ensures consistent quality in perishable or fragile items.

Case Study: A food processing factory in Shenzhen installed Drez floor-standing AC units combined with industrial refrigeration. The system maintained 4°C in storage areas year-round, reducing spoilage rates by 20%.

Choosing the Right Supplier or Manufacturer

Selecting a reliable manufacturer is as important as choosing the right system:

- Technical Support & Service: Look for companies offering installation, maintenance, and 24/7 technical support.

- Customization Options: Some factories require tailored solutions for unique layouts or processes.

- Proven Track Record: Case studies and client testimonials demonstrate reliability.

Brand Note: Drez Aircon provides industrial and factory AC solutions, offering high-capacity units, portable options, and integrated refrigeration systems with global support. Their solutions are deployed in warehouses, manufacturing plants, and temporary industrial setups worldwide.

Frequently Asked Questions (FAQs)

1. What is a factory air conditioner refrigerator?

A factory air conditioner refrigerator is an industrial-grade cooling and refrigeration system designed to control temperature in manufacturing plants, warehouses, and production environments. It helps maintain worker comfort, protects machinery, and ensures stable conditions for temperature-sensitive products.

2. Why do factories need specialized industrial AC and refrigeration systems?

Factories generate high heat loads from machinery, production processes, and large crowds of workers. Standard commercial AC cannot handle these demands. Industrial systems offer higher cooling capacity, durability, and efficient continuous operation.

3. What capacity factory air conditioner refrigerator do I need for my plant?

Capacity depends on floor size, heat load, ceiling height, insulation, number of workers, and type of production. Cooling capacity is usually measured in tons or kW. A professional HVAC evaluation helps determine the exact requirement.

4. What industries commonly use factory air conditioner refrigerators?

They are widely used in manufacturing plants, food processing units, pharmaceutical facilities, electronics factories, logistics warehouses, chemical plants, textile factories, and metal processing industries.

5. Are portable or packaged factory AC units better for industrial plants?

Portable units are ideal for temporary or zone-based cooling, while packaged or centralized systems are better for large facilities requiring uniform cooling. The right choice depends on usage, mobility needs, and long-term plans.

6. How important is energy efficiency in industrial factory AC systems?

Very important. Energy-efficient systems reduce operational costs, lower electricity usage, and minimize environmental impact. Look for systems with high energy performance ratings, advanced compressors, and eco-friendly refrigerants.

7. How often should a factory air conditioner refrigerator be maintained?

Routine maintenance should be carried out every 3–6 months, depending on operational load. This includes filter cleaning, coil inspection, refrigerant checks, and system diagnostics to avoid breakdowns and ensure long lifespan.

8. Can an industrial air conditioner also manage humidity control?

Yes. Many factory AC systems include humidity control to maintain stable conditions. This is especially important in electronics, pharmaceutical, food production, and printing industries where moisture affects product quality.

9. What are the main benefits of installing an industrial AC and refrigeration system in a factory?

Key benefits include improved employee comfort, stable production environments, protection of heat-sensitive machinery, reduced spoilage of stored goods, stable product quality, and better overall operational efficiency.

10. How do I choose the right supplier for a factory air conditioner refrigerator?

Choose a supplier with industrial expertise, strong technical support, proven case studies, custom engineering capability, and reliable after-sales service. Brands like Drez Aircon provide industrial-grade cooling solutions designed for factories, warehouses, and large production environments.

Conclusion

Selecting the best factory air conditioner refrigerator involves understanding your plant’s size, temperature requirements, and production needs. Factors like energy efficiency, durability, integration with existing systems, and reliable supplier support ensure you get a solution that improves productivity, protects equipment, and maintains product quality. By considering these elements, industrial plants can optimize their operations, reduce costs, and provide a safe environment for employees.

Investing in a high-quality industrial AC and refrigeration system is not just about cooling – it’s about operational efficiency, reliability, and long-term cost savings.