يعد فهم الضاغط أمرًا ضروريًا لإتقان كيفية عمل أنظمة تكييف الهواء التجارية.باعتباره قلب كل وحدة HVAC، يقوم الضاغط بتشغيل دورة التبريد، مما يضمن التحكم المتسق في درجة الحرارة وكفاءة الطاقة وموثوقية النظام.سواء في مباني المكاتب أو مراكز البيانات أو المنشآت الصناعية، فإن اختيار الضاغط المناسب لا يحدد قوة التبريد فحسب، بل يحدد أيضًا توفير التكاليف على المدى الطويل.في هذا الدليل، سنستكشف كل شيء بدءًا من كيفية عمل الضواغط وحتى كيفية اختيار النموذج المثالي لنشاطك التجاري من خلال رؤى الخبراء من شركةDrezaircon، وهي إحدى الشركات التجارية الرائدة في الصينفي مجال تصنيع مكيفات الهواء.

ما هو ضاغط مكيف الهواء التجاري؟

أضاغط مكيف الهواء التجاريهو جهاز ميكانيكي يعمل على زيادة ضغط بخار مادة التبريد، وتحويله من غاز منخفض الضغط إلى غاز عالي الضغط قبل مروره عبر المكثف.هذه العملية أساسية لدورة التبريد.

بينما تعمل الضواغط السكنية الصغيرة بشكل متقطع، تم تصميم الضواغط التجارية لضمان المتانة والأداء المستمر، وغالبًا ما تعمل لساعات طويلة في ظروف الأحمال العالية مثل مراكز التسوق والمستشفيات والمصانع.

كيف تعمل ضواغط مكيفات الهواء التجارية؟

يعمل الضاغط التجاري كجزء من دورة التبريد المغلقة.يقوم بضغط غاز التبريد مما يرفع درجة حرارته وضغطه.ثم يتحرك الغاز الساخن عبر المكثف، حيث يطلق الحرارة ويتحول إلى سائل.ينتقل سائل التبريد هذا بعد ذلك إلى المبخر، ويمتص الحرارة من البيئة، ويبرد الهواء قبل أن يعود إلى الضاغط.

في المبردات المبردة بالهواء، يطلق النظام الحرارة إلى الهواء المحيط، بينما تستخدم المبردات المبردة بالماء برج تبريد لتبديد الحرارة بشكل أكثر كفاءة.تصمم شركةDrezairconأنظمة ضاغطة مُحسَّنة لكلا الإعدادين، مما يضمن كفاءة عالية حتى في ظروف درجات الحرارة المتقلبة الشائعة عبر المناخات المتنوعة في الصين.

أنواع ضواغط مكيفات الهواء التجارية

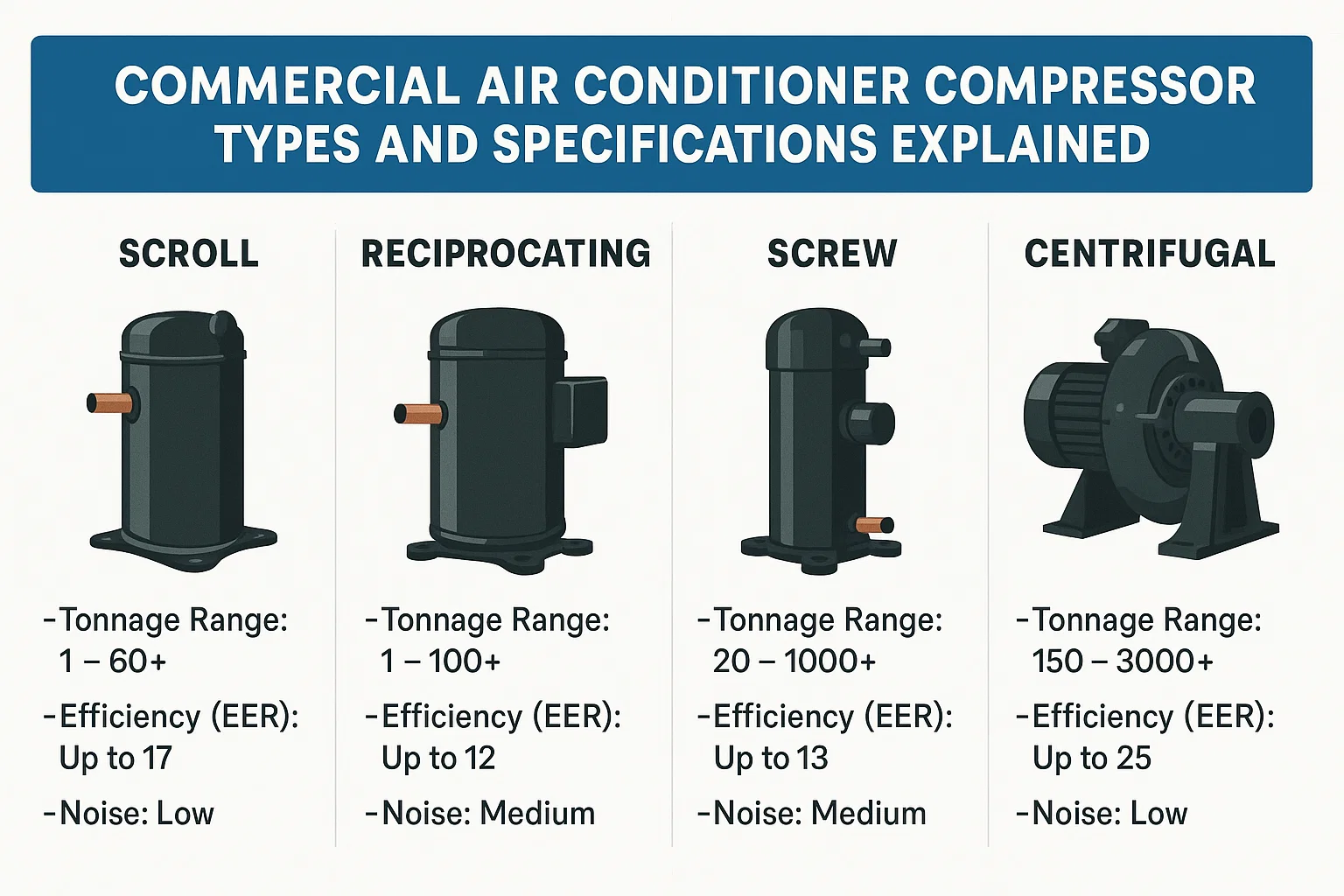

تتطلب التطبيقات المختلفة أنواعًا مختلفة من الضواغط، ويقدم كل منها مزايا فريدة:

- الضواغط الترددية– تستخدم هذه المكابس لضغط مادة التبريد وهي مثالية للمساحات التجارية الصغيرة والمتوسطة الحجم.

- الضواغط التمريرية– تتميز الضواغط التمريرية المدمجة والهادئة بالكفاءة العالية ويشيع استخدامها في مباني المكاتب وبيئات البيع بالتجزئة.

- الضواغط اللولبية– مصممة للاستخدام الصناعي على نطاق واسع، فهي توفر التشغيل المستمر والأداء المستقر للمصانع ومراكز البيانات.

- ضواغط الطرد المركزي– الأفضل للأنظمة ذات السعة العالية مثل المطارات أو ناطحات السحاب؛يتعاملون مع أحمال التبريد الكبيرة بكفاءة.

- الضواغط الدوارة– مناسبة للوحدات التجارية الصغيرة التي تتطلب التوازن بين الأداء والتصميم المدمج.

تقومDrezairconبتصنيع جميع أنواع الضواغط الرئيسية، مما يضمن أن العملاء يمكنهم اختيار الخيار الأكثر ملاءمة لمقياس التشغيل ومتطلبات التبريد الخاصة بهم.

لماذا تعتبر الضواغط جوهر كل نظام تبريد؟

في كل نظام تكييف هواء تجاري، يقوم الضاغط بمهمة حيوية تتمثل في توزيع مادة التبريد عبر النظام.وهو مسؤول عن ضغط مادة التبريد وتحريكها بين المبخر وملفات المكثف، مما يتيح نقل الحرارة مما يجعل التبريد ممكنًا.

بالنسبة للمنشآت التجارية والصناعية، يؤثر هذا المكون بشكل مباشر على تكاليف التشغيل ومستويات الراحة وكفاءة الطاقة.

يضمن الضاغط عالي الجودة أداء أنظمة التبريد بفعالية في ظل الطلب الكبير، وهو أمر تقدره الشركات في المناطق الحارة والرطبة في الصين بشكل خاص.Drezairconمتخصص في تطوير الضواغط المتقدمة المصممة لهذه البيئات الصعبة، مما يضمن الموثوقية والاستدامة.

دور الضواغط في المبردات المبردة بالهواء والمبردة بالماء

تستخدم المبردات المبردة بالهواء الهواء الخارجي لإزالة الحرارة، كما أنها أسهل في التركيب والصيانة، مما يجعلها مثالية للمواقع ذات إمدادات المياه المحدودة.من ناحية أخرى، تعتمد المبردات المبردة بالماء على مصدر مياه وبرج تبريد، مما يوفر كفاءة أعلى في البيئات واسعة النطاق أو الصناعية.

يتطلب كل نوع من أنواع المبردات إعدادًا محددًا للضاغط –Drezairconيخصص كلاً من أنظمة الضاغط المبردة بالهواء والمبردة بالماء لإدارة الحمل بدقة والاستخدام الأمثل للطاقة.

تحديد حجم الضاغط للمباني التجارية الكبيرة

يعد الحجم الصحيح للضاغط أمرًا بالغ الأهمية لكفاءة الطاقة وطول عمر النظام.سوف يعمل الضاغط الصغير الحجم بشكل زائد عن الحد، مما يؤدي إلى فشل مبكر، في حين أن الوحدة كبيرة الحجم ستدور بشكل متكرر للغاية، مما يؤدي إلى إهدار الطاقة.

لتحديد الحجم بشكل صحيح، يقوم المهندسونبحسابات حمل التبريد، مع الأخذ في الاعتبار عوامل مثل:

- المساحة الإجمالية وارتفاع المبنى

- الإشغال وتوليد الحرارة المعدات

- جودة العزل والتعرض للزجاج

- مستويات المناخ والرطوبة

يستخدم مهندسوDrezairconأدوات وصيغ محاكاة الحمل المتقدمة مثل BTU وحسابات الحمولة للتوصية بحجم الضاغط الأكثر ملاءمة لكل نوع من أنواع المباني.

تصميم نظام التدفئة والتهوية وتكييف الهواء الصناعي واختيار الضاغط

يسير اختيار الضاغط جنبًا إلى جنب مع تصميم نظام التدفئة والتهوية وتكييف الهواء (HVAC).يضمن الضاغط المناسب تدفق هواء متوازن وضغطًا ثابتًا وتبادلًا حراريًا فعالاً.تتطلب الأنظمة الصناعية في الصين غالبًا ضواغط قوية قادرة على العمل على مدار الساعة طوال أيام الأسبوع في البيئات المتربة ذات درجات الحرارة العالية.

تصمم شركة Drezaircon ضواغطها لتتناسب مع الصناعات المختلفة، بدءًا من تصنيع الأدوية وإنتاج المنسوجات وحتى تبريد الخوادم وتبريد المستودعات، مما يضمن التحكم الدقيق وتحسين الطاقة.

خيارات الضاغط لوحدات تكييف الهواء على السطح

تحظى أنظمة تكييف الهواء على الأسطح بشعبية كبيرة في المباني التجارية نظرًا لكفاءتها في المساحة وانخفاض مستوى الضجيج الداخلي.ومع ذلك، تواجه الضواغط في هذه الأنظمة ظروفًا بيئية قاسية.

لضمان الموثوقية،تم تصميم ضواغط السطح من Drezirconبأغطية مقاومة للطقس، والتحكم في الاهتزازات، وأنظمة تشحيم متقدمة للتعامل مع تقلبات درجات الحرارة والتعرض الخارجي.

ضواغط نظام التبريد الصناعي والتجاري

في حين أن التكنولوجيا المستخدمة في الضواغط قد تتداخل، فإن متطلبات التشغيل تختلف بشكل كبير بين الاستخدامات الصناعية والتجارية.تتطلب الأنظمة الصناعية أداءً قويًا وإنتاجية عالية السعة، في حين تعطي الضواغط التجارية الأولوية لكفاءة الطاقة والتشغيل الهادئ.

يغطي خط إنتاج Drezirconكلا القطاعين، ويقدم حلولًا مخصصة تعمل على زيادة العمر الافتراضي إلى أقصى حد والحفاظ على الأداء المتفوق.

العوامل التي تؤثر على أداء الضاغط

تؤثر العديد من المتغيرات البيئية والتشغيلية على كفاءة الضاغط وموثوقيته:

- درجة الحرارة المحيطة:قد تؤدي درجات الحرارة الخارجية المرتفعة إلى إجهاد الضواغط وتقليل الكفاءة.

- الرطوبة:تؤثر الرطوبة الزائدة على سلوك مادة التبريد والتعامل مع الأحمال.

- جودة الصيانة:تعمل الخدمة المنتظمة على إطالة العمر التشغيلي للضاغط.

- معايير التثبيت:يضمن التثبيت الصحيح تدفقًا ثابتًا لسائل التبريد ويقلل من فقدان الطاقة.

تلتزمDrezairconببروتوكولات اختبار الأداء الصارمة لضمان تقديم الضواغط لأفضل النتائج في الظروف الواقعية.

ضواغط تكييف الهواء التجارية الموفرة للطاقة

ومع ارتفاع تكاليف الطاقة واللوائح البيئية، أصبحت الكفاءة الآن أولوية قصوى.تشتملضواغطDrezairconعلى تقنيات متقدمة مثل محركات التردد المتغير (VFDs) التي تضبط السرعة والطاقة تلقائيًا بناءً على الطلب، مما يقلل من استهلاك الطاقة بنسبة تصل إلى 30%.

بالإضافة إلى ذلك، تستخدم العلامة التجارية مبردات صديقة للبيئة ذات قدرة منخفضة على إحداث الاحترار العالمي وأنظمة مراقبة ذكية تكتشف مشكلات الأداء مبكرًا لتقليل وقت التوقف عن العمل.

الابتكارات التكنولوجية تشكل الضواغط الحديثة

تستفيد الضواغط الحديثة من البحث المستمر والتطور التكنولوجي.تسمح ميزات مثلالتمرير الرقميوالضواغط العاكسةبالتعديل الدقيق، مما يضمن تبريدًا متسقًا دون هدر طفرات في الطاقة.

يواصل Drezirconالابتكار في أنظمة الصيانة التنبؤية التي تستخدم الذكاء الاصطناعي للتنبؤ بالتآكل الميكانيكي وتعزيز الموثوقية العامة، مما يجعل الشركات في الصين في صدارة منحنى كفاءة التدفئة والتهوية وتكييف الهواء (HVAC).

اعتبارات التثبيت للضواغط التجارية

التثبيت السليم هو مفتاح الأداء على المدى الطويل.تؤثر عوامل مثل إعداد الموقع، وتخطيط الأنابيب، والإعدادات الكهربائية بشكل مباشر على الكفاءة.

يجب أن يضمن القائمون على التركيب ما يلي:

- أسس آمنة ومستوية للتحكم في الاهتزازات

- التهوية الكافية لتبديد الحرارة

- توفر المحاذاة الصحيحة لغاز التبريد وخطوط الكهرباء

Drezairconإرشادات التثبيت الاحترافية وفرق الخدمة المدربة وفقًا لمعايير السلامة والأداء الوطنية في الصين.

أفضل ممارسات الصيانة واستكشاف الأخطاء وإصلاحها

الصيانة الدورية غير قابلة للتفاوض بالنسبة للضواغط ذات السعة العالية.تساعد عمليات الفحص الروتينية لمستويات الزيت وشحن سائل التبريد وحالة المحرك على تجنب الأعطال المكلفة.

تشمل العلامات الشائعة لمشاكل الضاغط الضوضاء المفرطة أو الحرارة الزائدة أو الانخفاض المفاجئ في الضغط.يقدم دعم ما بعد البيع من Drezairconتشخيصات وخطط خدمة مصممة للحفاظ على تشغيل الأنظمة بكفاءة على مدار العام.

الضواغط حسب الشركة المصنعة – مجموعة منتجات Drezaircon المتقدمة

Drezairconتنتج مجموعة واسعة من الضواغط، بما في ذلك:

- الضواغط الحلزونية واللولبيةللحصول على أداء فعال وصيانة منخفضة

- الضواغط الصناعية عالية السعةلتشغيل المصنع على مدار الساعة طوال أيام الأسبوع

- ضواغط الأسطح المدمجةمصممة للمباني التجارية الحضرية

تم تصميم كل خط إنتاج لتلبية المتطلبات الصناعية للصين ومعايير الكفاءة العالمية، مما يضمن الموثوقية على المدى الطويل وانخفاض تكاليف التشغيل.

الأسئلة المتداولة

ما هو الضاغط الأكثر كفاءة للأنظمة التجارية؟

تعتبر الضواغط التمريرية والعاكسة من أكثر الخيارات كفاءة لأنظمة التدفئة والتهوية وتكييف الهواء التجارية.توفر الضواغط الحلزونية تشغيلًا سلسًا وموثوقًا مع عدد أقل من الأجزاء المتحركة، مما يؤدي إلى انخفاض احتياجات الصيانة والمتانة على المدى الطويل.من ناحية أخرى، تقوم الضواغط التي تعمل بالعاكس بضبط سرعتها تلقائيًا بناءً على طلب التبريد.تعمل هذه التقنية ذات السرعة المتغيرة على تقليل هدر الطاقة، وتضمن راحة داخلية متسقة، وتقلل بشكل كبير من تكاليف الكهرباء، مما يجعلها مثالية للبيئات التجارية حيث تكون الكفاءة والموثوقية على رأس الأولويات.

كم مرة يجب أن أقوم بصيانة الضاغط التجاري الخاص بي؟

يعتمد تكرار صيانة الضاغط على حجم عمل النظام وبيئة التشغيل.بالنسبة للمنشآت ذات الاستخدام الكثيف أو المستمر، مثل مراكز التسوق أو وحدات التصنيع أو مراكز البيانات، يوصى بشدة بالصيانة ربع السنوية.تساعد الصيانة الدورية على اكتشاف علامات التآكل المبكرة، ومنع الأعطال، والحفاظ على كفاءة الطاقة المثلى.في التطبيقات التجارية الأخف مثل المكاتب أو متاجر البيع بالتجزئة، تكون الخدمة الشاملة كل ستة أشهر كافية بشكل عام للحفاظ على تشغيل النظام بسلاسة، وإطالة عمر الضاغط، وتجنب تكاليف الإصلاح غير المتوقعة.

هل تقدم شركة Drezaircon ضواغط مصممة خصيصًا؟

نعم، شركة Drezaircon متخصصة في تصميم وتصنيع أنظمة الضواغط المصممة خصيصًا لتتوافق مع متطلباتك الدقيقة.سواء كنت بحاجة إلى حل للتبريد عالي السعة، أو التشغيل منخفض الضوضاء، أو توفير الحد الأقصى من الطاقة، يقوم مهندسو Drezaircon بتصميم كل وحدة بناءً على حمل التبريد المحدد لمشروعك، والظروف البيئية، وأهداف الاستدامة.

ويضمن هذا النهج المخصص الأداء الأمثل والكفاءة والموثوقية، مما يجعل Drezaircon خيارًا موثوقًا به لحلول التبريد التجارية المخصصة.

الخلاصة – لماذا تختار شركة Drezaircon لضواغط مكيفات الهواء التجارية في الصين

يعد اختيار ضاغط مكيف الهواء التجاري المناسب قرارًا يؤثر على تكاليف الطاقة والموثوقية والراحة العامة.بفضل خبرتها العميقة في هندسة التدفئة والتهوية وتكييف الهواء، تقفDrezairconكشركة مصنعة موثوقة في صناعة التبريد في الصين، حيث تقدم أنظمة ضاغطات متقدمة وفعالة ومتينة.

من خلال الجمع بين الابتكار والخبرة المحلية، تضمن Drezaircon بقاء عملك باردًا وفعالًا ومستدامًا بغض النظر عن مدى تطلب احتياجات التبريد الخاصة بك.