Industrial Air Dome Air Conditioner systems have become an essential solution for large-scale cooling in factories, warehouses, industrial tents, and temporary structures. Designed to provide high-capacity airflow and reliable temperature control, these specialized AC units ensure optimal working conditions in environments where traditional cooling systems often fall short.

With their robust construction, energy-efficient performance, and flexibility for both permanent and temporary installations, industrial air dome air conditioners are ideal for a variety of commercial and industrial applications.

From industrial events and exhibitions to factory floors and large storage areas, these systems can handle demanding cooling requirements while maintaining efficiency and operational reliability. Proper installation, regular maintenance, and timely troubleshooting are critical to maximize the lifespan and performance of these units.

In this guide, we will explain the complete installation and maintenance process for industrial air dome air conditioners, ensuring you get the most effective and long-lasting cooling solution for your industrial needs.

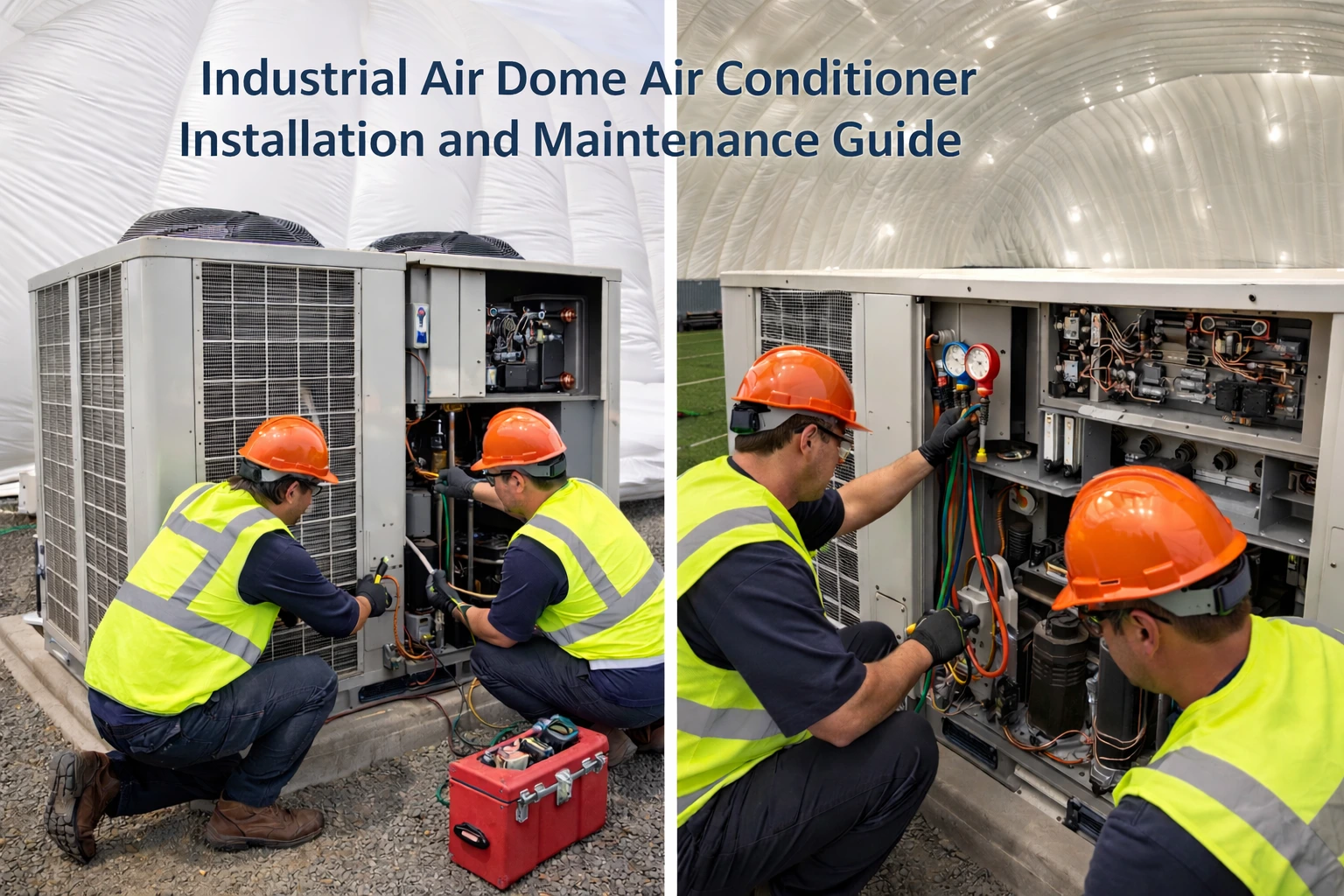

Industrial Air Dome Air Conditioner Installation and Maintenance Guide

Industrial Air Dome Air Conditioner systems are becoming an essential solution for large-scale cooling in factories, warehouses, and industrial tents. With their high-capacity airflow, energy-efficient operation, and reliability, these specialized air conditioning units provide an optimal environment for industrial processes and temporary structures where standard cooling systems fall short.

Proper installation, routine maintenance, and timely troubleshooting are critical to ensure maximum performance and longevity of these units. In this guide, we will explain the complete installation and maintenance process for industrial air dome air conditioners, ensuring you get the most effective cooling solution for your industrial needs.

1. Introduction to Industrial Air Dome Air Conditioners

Industrial air dome air conditioners are specialized commercial and industrial HVAC systems designed to handle high-volume cooling for large structures. Unlike standard AC units, these systems can cool spaces such as factory floors, large tents, warehouses, and temporary event structures efficiently. Their modular and portable designs allow flexibility in placement and installation, making them suitable for both permanent and temporary applications.

Applications include:

- Industrial factories requiring high airflow for production areas

- Large storage warehouses needing temperature control

- Event tents and exhibition halls where temporary cooling is essential

- Military or research temporary structures

Industrial air dome systems typically feature high-capacity compressors, energy-efficient blowers, and ducted or non-ducted airflow, allowing them to provide uniform cooling across large areas. With proper maintenance and installation, these units can operate efficiently for years.

2. Types of Industrial Air Dome Air Conditioners

Understanding the types of industrial air dome air conditioners is essential before installation. The main categories include:

2.1 Portable Industrial AC Units

Portable industrial air dome AC units are compact, modular systems that can be easily moved to different areas. They are ideal for temporary cooling in large tents or event spaces and can handle medium to large industrial areas.

2.2 High-Capacity Dome AC Systems

These are permanent or semi-permanent installations for factories and large warehouses. They are designed for continuous operation, with higher tonnage capacity and robust construction to handle industrial demands.

2.3 Energy-Efficient Industrial HVAC Solutions

Modern industrial air dome air conditioners come with energy-efficient technology, including variable-speed compressors, optimized airflow ducts, and smart thermostatic control. This reduces operational costs, especially for large-scale operations.

2.4 Commercial vs Temporary Solutions

- Commercial dome AC systems are intended for permanent installations in industrial facilities.

- Temporary or event-based systems are portable, quick to install, and designed for short-term use.

3. Pre-Installation Considerations

Before installing an industrial air dome air conditioner, several factors must be evaluated to ensure optimal performance.

3.1 Determining Cooling Capacity

The first step is to calculate the cooling load of the space. Factors include:

- Total square footage or volume of the structure

- Number of occupants or machinery generating heat

- Heat gain from sunlight or industrial processes

For example, a 10,000 sq. ft. factory floor with moderate machinery may require an industrial AC unit of 30–50 tons capacity.

3.2 Site Preparation

- Ensure flat, stable flooring for unit placement

- Check clearances around the unit for proper airflow

- Verify ventilation paths for ducted or non-ducted units

3.3 Power Requirements

Industrial AC units consume significant power. Check:

- Voltage and amperage requirements

- Dedicated electrical circuits

- Backup power options for critical operations

3.4 Choosing Between Portable and Fixed Systems

Decide if a portable unit or a fixed industrial dome AC is best:

- Temporary structures → portable units

- Permanent industrial facilities → fixed, high-capacity systems

4. Step-by-Step Installation Guide

Proper installation is key to ensuring performance and longevity of industrial air dome air conditioners.

4.1 Unpacking and Inspection

- Check for damage during shipping

- Verify that all components and manuals are included

- Inspect compressor, blower, filters, and ducts

4.2 Positioning the Unit

- Place the unit in a location with adequate clearance

- Avoid obstacles blocking airflow

- For temporary structures, ensure stability and protection from wind or rain

4.3 Electrical and Duct Connections

- Connect to the appropriate electrical supply

- For ducted units, ensure ducts are correctly sealed to prevent leaks

- Confirm grounding and safety compliance

4.4 Testing Airflow and Cooling Efficiency

- Turn on the system and verify cooling performance

- Check for unusual noises or vibrations

- Ensure even airflow distribution across the structure

5. Operational Tips for Industrial Air Dome AC

5.1 Optimal Temperature Settings

- Maintain industrial spaces between 22–26°C for comfort and machinery efficiency

- Adjust settings for energy efficiency during low-occupancy periods

5.2 Energy-Saving Practices

- Use variable speed compressors if available

- Ensure all doors and windows are closed during operation

- Schedule routine operational checks to maintain efficiency

5.3 Integration with HVAC Systems

- Industrial air dome AC units can be integrated with existing ducting

- Can supplement or replace older commercial HVAC systems

6. Maintenance Guide for Industrial Air Dome AC

Routine maintenance ensures longevity, reliability, and preventive troubleshooting.

6.1 Routine Inspection Checklist

- Check filters, ducts, and blowers

- Inspect compressor and refrigerant levels

- Ensure electrical connections are secure

6.2 Cleaning and Servicing

- Clean air filters monthly

- Remove dust from internal components

- Lubricate moving parts as recommended by the manufacturer

6.3 Troubleshooting Common Issues

- Reduced airflow → Check ducts or dirty filters

- Uneven cooling → Inspect compressor and airflow distribution

- Electrical faults → Verify voltage, fuses, and wiring connections

7. Safety Guidelines

- Always turn off power before servicing

- Handle refrigerants according to safety standards

- Avoid placing units near combustible materials

- Follow manufacturer instructions and safety manuals

8. Upgrading and Replacing Components

- Replace filters every 3–6 months

- Upgrade compressors or blowers for efficiency

- Enhance airflow capacity for larger structures

- Schedule professional inspection annually

9. Case Study: DrezAircon Industrial Dome AC in Action

A large industrial warehouse in Guangzhou installed a DrezAircon industrial air dome air conditioner of 40-ton capacity. The system reduced ambient temperature by 8–10°C within 30 minutes, maintained airflow across 12,000 sq. ft., and reduced energy costs by 15% compared to their old commercial AC system. Routine maintenance, including filter cleaning and compressor inspection, ensured no downtime during peak summer months, demonstrating the reliability of properly installed industrial dome AC systems.

FAQs: Industrial Air Dome Air Conditioner

1. What is an industrial air dome air conditioner?

An industrial air dome air conditioner is a high-capacity cooling system designed for large spaces such as factories, warehouses, industrial tents, and temporary event structures. These units provide efficient airflow, energy savings, and reliable temperature control for commercial and industrial applications.

2. How do I choose the right industrial air dome AC for my space?

Selection depends on space size, occupancy, heat-generating equipment, and cooling load. Portable units are suitable for temporary structures, while high-capacity fixed systems are ideal for permanent industrial facilities.

3. What is the installation process for an industrial air dome air conditioner?

The installation involves site preparation, electrical connection, positioning, duct setup (if required), and testing airflow. Proper installation ensures optimal performance and longevity.

4. Can industrial air dome AC units be used in temporary event structures?

Yes. Portable industrial air dome air conditioners are designed for temporary applications like weddings, exhibitions, and industrial events. They offer quick setup, mobility, and high cooling capacity.

5. How often should I maintain my industrial air dome AC?

Routine maintenance should be performed monthly for filters and airflow checks, and every 6–12 months for comprehensive inspections including compressors, electrical systems, and refrigerant levels.

6. What are common problems with industrial air dome air conditioners?

Common issues include reduced airflow, uneven cooling, unusual noise, and electrical faults. These can usually be addressed through cleaning, inspection, and professional servicing.

7. How energy-efficient are industrial air dome air conditioners?

Modern industrial air dome AC units are equipped with variable-speed compressors, optimized airflow, and smart controls, which reduce energy consumption compared to traditional industrial AC systems.

8. Can I integrate an industrial air dome AC with existing HVAC systems?

Yes. Many systems can connect with existing ducting and commercial HVAC networks, providing supplemental cooling or replacing outdated units while maintaining airflow efficiency.

9. How long does an industrial air dome air conditioner last?

With proper installation, regular maintenance, and timely component replacement, industrial air dome AC units can last 10–15 years, depending on usage and environmental conditions.

10. Where can I buy or service industrial air dome air conditioners?

Leading manufacturers and suppliers like DrezAircon provide industrial air dome AC units, professional installation, maintenance services, and spare parts. Always choose a trusted provider to ensure reliable performance and warranty coverage.

Conclusion

Industrial air dome air conditioners are essential for large-scale industrial, commercial, and event spaces. Proper pre-installation planning, accurate placement, electrical setup, and regular maintenance ensure efficient cooling, energy savings, and long-term reliability.

By following safety guidelines, performing routine inspections, and upgrading components as necessary, facility managers can maximize the lifespan and performance of these high-capacity systems.

Proper installation, including careful site preparation, accurate electrical setup, and correct positioning, is critical to achieving optimal performance. Equally important is regular maintenance cleaning filters, checking airflow, inspecting compressors, and addressing minor issues promptly to ensure longevity, reliability, and energy efficiency.

By following the guidelines outlined in this guide, facility managers and industrial operators can maximize the lifespan of their air dome AC units, maintain consistent cooling, and reduce operational costs. Whether you are managing a permanent factory installation or a temporary industrial tent, understanding the installation and maintenance process empowers you to make informed decisions and ensures that your space remains comfortable and productive year-round.