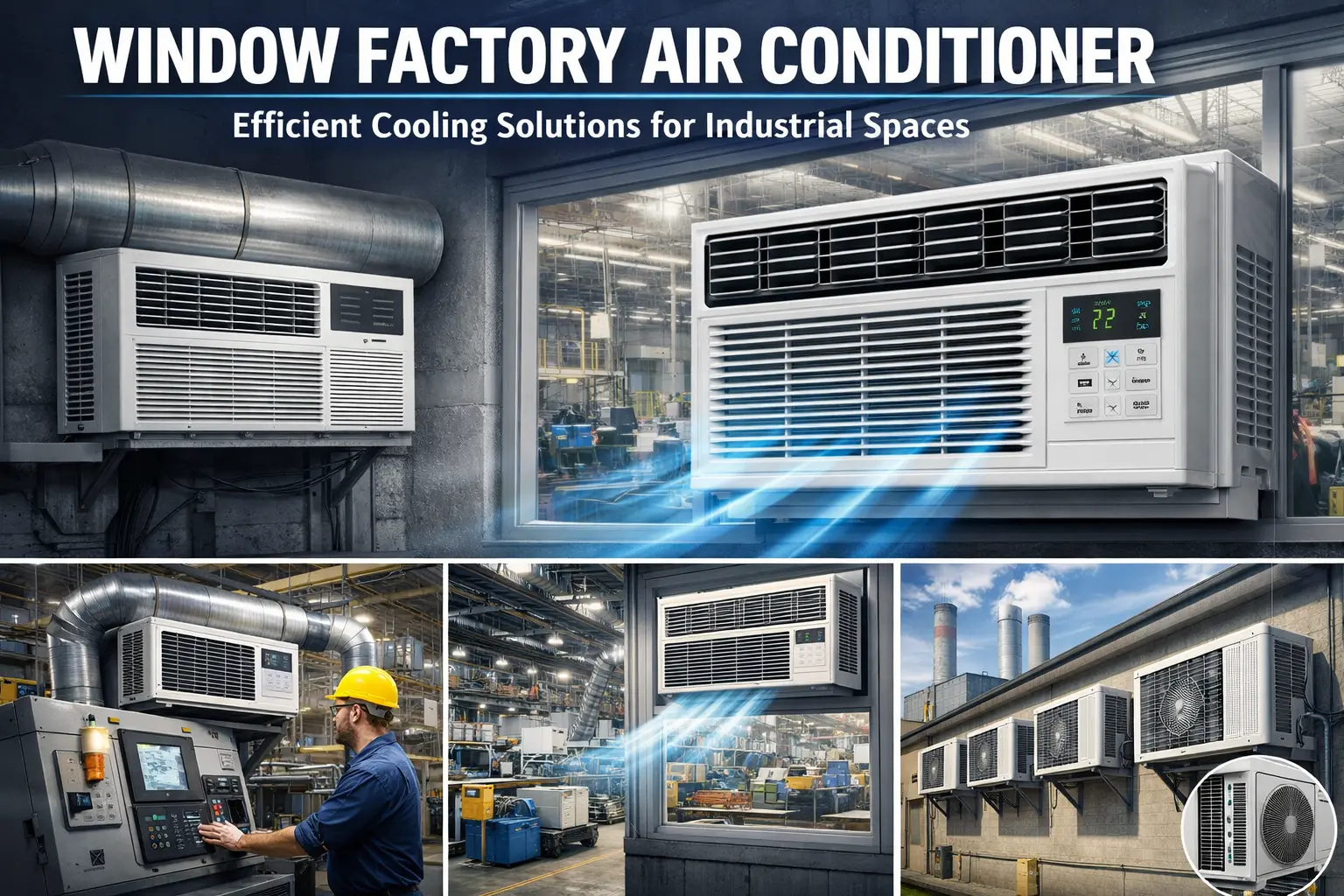

Window Factory Air Conditioner systems have become an essential solution for modern industrial spaces, offering a practical and efficient approach to maintaining optimal temperatures in factories, warehouses, and production facilities. Unlike standard residential air conditioning units, these industrial-grade window ACs are designed to handle large open areas, high heat loads, and continuous operation, making them ideal for facilities where centralized HVAC systems may be impractical or cost-prohibitive.

Factories generate heat from machinery, lighting, and human activity, which can negatively affect both equipment efficiency and worker comfort. Installing a window air conditioner in factory settings provides targeted cooling, allowing managers to create controlled zones for production lines, storage areas, or staff working spaces. These units are often modular, energy-efficient, and easy to maintain, providing reliable cooling without extensive installation costs or downtime.

Furthermore, industrial window ACs contribute to better air quality and ventilation, reducing dust, contaminants, and excess humidity that can impact product quality or employee health. For industrial facility managers seeking a cost-effective, flexible, and efficient cooling solution, these units represent a smart investment.

Window Factory Air Conditioner: Efficient Cooling Solutions for Industrial Spaces

In this guide, we will explain everything you need to know about choosing, installing, and maintaining a best window factory air conditioner for your industrial space.

1. Introduction: Why Window Factory Air Conditioners Are Essential for Industrial Spaces

Industrial facilities, including factories, warehouses, and production plants, require effective cooling solutions to maintain productivity, equipment efficiency, and employee comfort. Unlike small residential spaces, factories often face high heat loads due to machinery, lighting, and large open spaces. Installing a window factory air conditioner provides a practical solution for such industrial environments.

Window-mounted AC units are compact, energy-efficient, and modular, making them suitable for facilities where installing central HVAC systems may not be cost-effective. These units offer targeted cooling, allowing factory managers to control temperature zones efficiently.

Using industrial window air conditioners can improve air quality, reduce heat stress for workers, and protect temperature-sensitive equipment, ensuring smooth operations in manufacturing or storage environments.

2. Understanding Industrial Window Air Conditioner Systems

What Makes a Window AC Suitable for Factories

A window factory air conditioner differs from standard residential units in several ways:

- Cooling capacity: Typically designed to handle larger spaces, often measured in BTUs ranging from 24,000 to 120,000 depending on factory size.

- Durable construction: Heavy-duty compressors and reinforced casing can handle continuous operation in industrial conditions.

- Energy efficiency: Modern units are optimized to provide high cooling performance while keeping energy consumption manageable.

For example, Drez Aircon offers industrial AC units capable of handling large tents, factories, and exhibition halls, demonstrating how window-mounted or modular systems can scale to factory needs.

Key Features of Heavy-Duty and Modular Units

- Portable and modular designs: Units like Drez’s DCGN and DCTN series can be moved or installed in specific factory zones.

- High airflow volume: Ensures that even large workspaces receive adequate cooling.

- Flexible duct options: Some units allow for targeted airflow to critical areas, such as production lines or server rooms.

Energy-Efficient Industrial Air Conditioner Technologies

Modern units include variable-speed compressors, advanced refrigerants, and intelligent thermostat controls, reducing energy costs while maintaining optimal factory temperatures.

3. Advantages of Window Air Conditioners for Factories

Cost-Effective Factory Cooling Solutions

Installing window-mounted ACs in factories is generally less expensive than central HVAC systems. They do not require extensive ductwork or structural modifications, making them a practical choice for:

- Small and medium-sized factories

- Temporary factory setups

- Retrofit projects in existing buildings

Easy Installation and Maintenance for Industrial Spaces

Window factory air conditioners can be quickly installed in existing openings, reducing downtime for operations. Maintenance is also simplified:

- Filters can be cleaned or replaced without major disruption

- Routine checks for compressors and refrigerant levels are straightforward

Improving Factory Ventilation and Air Quality

Effective cooling is not just about temperature control. Industrial window AC units often include air filtration to remove dust and contaminants, which is critical in factories producing electronics, pharmaceuticals, or food products.

4. Choosing the Right Window AC for Your Industrial Facility

Factors to Consider: Cooling Capacity, BTU, and Factory Size

Selecting the right unit depends on:

- Factory area: Square footage determines the required BTU capacity

- Heat load: Consider machinery, lighting, and occupancy levels

- Installation site: Window dimensions, structural support, and electrical supply

For example, a factory space of 5,000 sq. ft may require a unit with 60,000–80,000 BTUs, while smaller workshops may operate efficiently with 24,000–36,000 BTUs.

Temporary Factory AC Solutions vs Permanent Installations

- Temporary solutions: Ideal for seasonal operations or pop-up production facilities; units can be moved or stored when not in use.

- Permanent installations: Provide consistent climate control for long-term factory operations and can be integrated with other ventilation systems.

Comparing Window AC Units vs Other Industrial HVAC Systems

Window ACs offer lower initial cost and faster deployment compared to:

- Central HVAC systems

- Split-type industrial air conditioners

- Ducted air distribution systems

They are ideal for targeted cooling or supplementary use alongside larger HVAC installations.

5. Installation and Maintenance Tips for Factory Window Air Conditioners

Proper Installation for Maximum Efficiency

- Place the unit in a window or opening with clear external airflow

- Ensure a tight seal to prevent energy loss

- Use support brackets or frames for heavy units to avoid structural strain

Preventive Maintenance for Long-Term Performance

- Clean filters monthly

- Inspect condenser coils and evaporators regularly

- Check refrigerant levels annually

- Lubricate moving components as needed

Safety and Operational Guidelines for Industrial Environments

- Maintain adequate electrical supply for high-capacity units

- Avoid placing units near heat-generating machinery

- Ensure compliance with industrial safety standards

6. Case Studies: Successful Industrial Applications of Window AC Units

Example 1: Small Factory Cooling Solution

A textile workshop in Guangdong installed a 36,000 BTU window AC unit per production hall. Result:

- Reduced ambient temperature by 8–10°C

- Improved employee comfort and productivity

- Minimized downtime caused by overheating machinery

Example 2: Large Warehouse or Production Facility

A food processing factory in Guangzhou used multiple heavy-duty window AC units to target critical zones:

- Installed 6 units with 80,000 BTU each

- Achieved consistent cooling across the 10,000 sq. ft. facility

- Integrated units with air filters to maintain hygiene standards

These examples demonstrate how modular, industrial window AC units can be customized for different factory sizes and requirements.

FAQS

1. What is a window factory air conditioner?

A window factory air conditioner is a heavy-duty, window-mounted AC unit designed to cool industrial spaces like factories, warehouses, and workshops. Unlike residential units, these are built for continuous operation, high heat loads, and large areas.

2. How does an industrial window air conditioner differ from a regular AC?

Industrial units have higher BTU capacity, reinforced compressors, and better airflow to handle factory-scale environments. They are also designed to maintain consistent cooling over long operating hours.

3. What size of window AC is needed for a factory?

The size depends on the factory area, heat load, and equipment. For example, a 5,000 sq. ft. space may require 60,000–80,000 BTUs, while smaller workshops can operate efficiently with 24,000–36,000 BTUs.

4. Can window AC units be used in large factories?

Yes, but multiple heavy-duty units are usually installed to achieve uniform cooling. Modular designs also allow targeted airflow in critical production zones.

5. Are industrial window AC units energy-efficient?

Modern units incorporate variable-speed compressors, advanced refrigerants, and intelligent thermostats, ensuring efficient cooling while reducing energy consumption.

6. How do I maintain a factory window air conditioner?

Regular maintenance includes cleaning filters, inspecting coils, checking refrigerant levels, and lubricating moving parts. Proper maintenance ensures longevity and consistent performance.

7. Can window AC units improve factory air quality?

Yes. Many industrial window ACs include air filtration that removes dust and contaminants, improving overall factory ventilation and worker health.

8. What is the difference between temporary and permanent window AC installations?

Temporary installations are ideal for seasonal or pop-up operations, while permanent units provide long-term climate control and can be integrated with other industrial HVAC systems.

9. Are window ACs cost-effective compared to central HVAC systems?

Yes. Window units offer lower upfront costs, easier installation, and minimal structural modifications, making them a practical choice for small to medium-sized factories.

10. How do I choose the right window AC for my factory?

Consider factors such as cooling capacity (BTU), factory size, heat load, installation site, and energy efficiency. Modular and heavy-duty units are recommended for industrial-scale cooling solutions.

Summary : Efficient and Reliable Cooling for Factories with Window Air Conditioners

Window factory air conditioners provide a practical, cost-effective, and energy-efficient solution for industrial cooling needs. They are ideal for:

- Small to medium-sized production facilities

- Temporary or modular setups

- Targeted cooling in zones with high heat loads

Choosing the right unit, following installation best practices, and maintaining the system ensures reliable performance and long-term operational efficiency.